Product

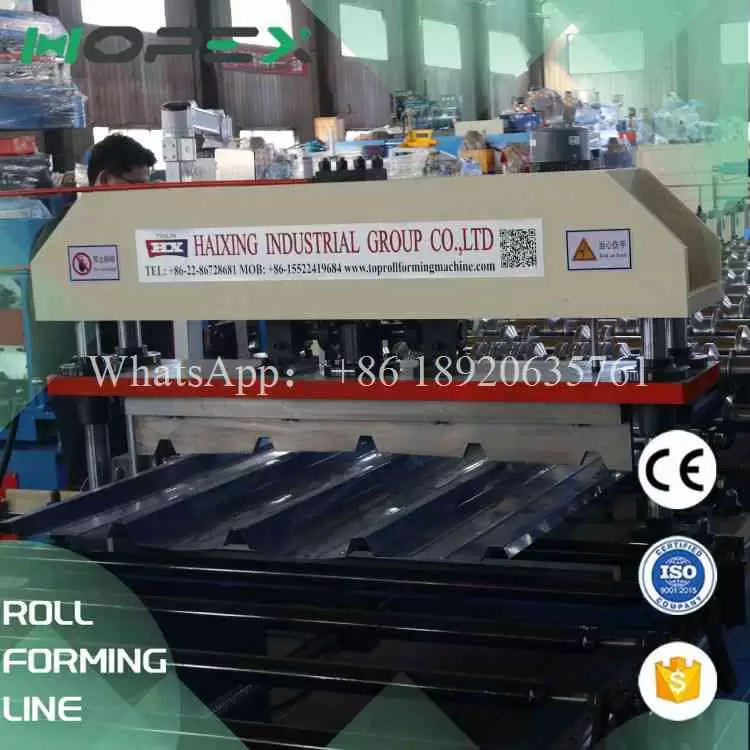

Professional trapezoidal sheet machine line

Double Layer Trapezoidal Sheet Machine Line: Maximizing Versatility in Structural Roof Panel Production

The relentless pursuit of efficiency and flexibility in modern metal construction drives continuous innovation in manufacturing technology. For producers seeking to expand their trapezoidal roofing sheet offerings without doubling their factory footprint or capital expenditure, the Double Layer Trapezoidal Sheet Machine Line presents a compelling engineering solution. This sophisticated integrated system is specifically designed to manufacture two distinct variations of high-demand trapezoidal metal roof panels on a single production platform. Its defining feature is the ability to operate either the upper or lower forming layer independently, providing manufacturers with unprecedented agility to switch between product profiles based on market demand, all within the confines of one streamlined double layer trapezoidal sheet machine line.

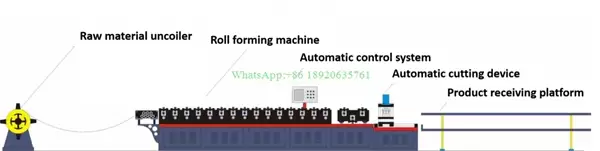

Roll Forming Process Workflow Diagram

More parameters

| Product Name | Double layer trapezoidal sheet machine Line |

| Main motor power | 5.5 kw |

| Hydraulic station | 4 kw |

| Produce speed | 10-15 m/min |

| Shaft material | 45# Steel |

| Touch screen | Delta or customized according to customer requirements |

| Rolling materials | 45# Steel |

| Cutting blade material | Cr12MoV, heat treatment HRC58-62℃ |

| Roller diameter | Φ70 mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 0.3-0.8 mm |

| Rows | 11+13 |

| Feeding width | 1250mm |

Strategic Advantages of the Double Layer Trapezoidal Sheet Machine Line:

Unmatched Production Flexibility: The ability to produce two distinct, high-value trapezoidal metal roof profiles on demand is the primary benefit. Manufacturers can respond instantly to specific customer orders or shifts in market preference without investing in a second full line.

Significant Capital Savings: Compared to purchasing and installing two separate trapezoidal lines, the double layer trapezoidal sheet machine line represents a major reduction in upfront investment. The shared decoiler, leveler, shear, stacker, controls, and structural frame contribute substantially to this cost efficiency.

Optimal Factory Footprint: Consolidating two production capabilities into a single line drastically reduces required factory floor space, freeing up valuable real estate for other operations or storage. The double layer trapezoidal sheet machine line maximizes space utilization.

Reduced Operational Complexity: Managing one integrated system with shared core components simplifies maintenance scheduling, spare parts inventory, operator training, and overall logistics compared to operating two independent machines.

Enhanced ROI: By enabling production of a broader product portfolio with a single asset, the double layer trapezoidal sheet machine line significantly improves return on investment. It allows manufacturers to capture a larger market share with diversified offerings.

Maintained Quality & Speed: Each dedicated forming path ensures the same high precision, consistency, and production speeds achievable on a single-profile line for its specific trapezoidal metal roof variant.

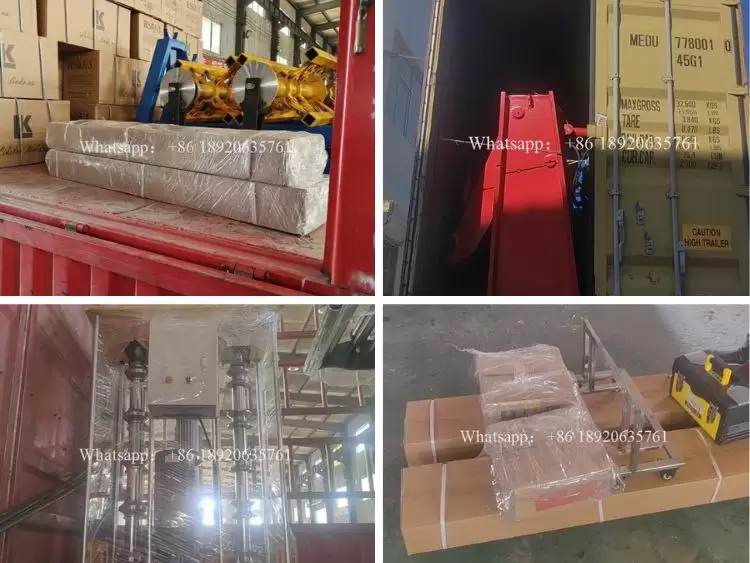

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a trapezoidal sheet machine Line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the trapezoidal sheet machine line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.