Product

Glazed Trapezoidal Custom Roll Forming Line

Dual-Profile Excellence: The Glazed Trapezoidal Double-Layer Custom Roll Forming Line

For 28 years, our engineering innovation has empowered manufacturers to conquer complex production challenges. We proudly present a groundbreaking solution for architectural metal and roofing specialists: the Glazed Trapezoidal Double-Layer Custom Roll Forming Line. This sophisticated, vertically integrated system redefines versatility, enabling the production of premium glazed metal roof tiles on the upper level and standard trapezoidal roof panels on the lower level – all within a single, space-efficient footprint. While operating one layer at a time, this unique custom roll forming line delivers unparalleled agility for manufacturers catering to diverse market segments, from high-end architectural projects requiring vibrant, durable glazed finishes to large-scale commercial or industrial applications needing robust trapezoidal profiles. Experience the pinnacle of flexible metal forming.

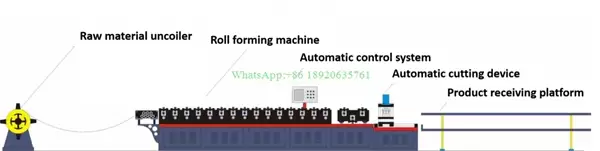

Roll Forming Process Workflow Diagram

More parameters

| Product Name | glazed trapezoidal double-layer custom roll forming line |

| Main motor power | 5.5 kw |

| Hydraulic station | 5.5 kw |

| Produce speed | 10-15 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12MoV, heat treatment HRC58-62℃ |

| Roller diameter | Φ70 mm |

| Voltage | 220v 60hz 3p be customized |

| Feeding thickness | 0.3-0.8 mm |

| Rows | 15+13 |

Machine Introduction: Engineered for Premium & Practical Production

The Glazed Trapezoidal Double-Layer Custom Roll Forming Line is an advanced, PLC-controlled manufacturing system featuring two fully independent production lines stacked vertically. It's meticulously engineered to handle two distinct product families:

Upper Layer: Dedicated to forming Glazed Metal Roof Tiles (Panels). This line processes pre-finished coils (typically PVDF-coated aluminum or steel) into intricate profiles mimicking traditional clay tiles, slate, or custom-designed glazed shingles. The forming process prioritizes precision to preserve the integrity of the delicate, high-gloss glazed finish.

Lower Layer: Dedicated to forming standard Trapezoidal Roof/Wall Panels. This line handles materials like galvanized steel (G.I.), Galvalume, or pre-painted steel (PPGI/PPGL), producing high-strength, cost-effective trapezoidal profiles for demanding structural applications.

Each layer operates as a self-contained custom roll forming line, featuring its own:

Heavy-duty decoiler with optional auto-loading

Progressive roll forming section with profile-specific stands

High-precision flying shear

Output run-out table with stacking/bundling

Independent PLC/HMI control station

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a glazed trapezoidal double-layer custom roll forming line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the glazed trapezoidal double-layer custom roll forming line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.