Product

Full-automatic metal roof sheet making machine line

Metal Roof Sheet Making Machine Line: Dual-Profile Precision for Corrugated and Trapezoidal Roofing

In the dynamic world of roofing manufacturing, versatility and efficiency are critical competitive advantages. The innovative metal roof sheet making machine line stands as a technological solution designed to meet diverse market demands. This highly integrated production system uniquely combines the capability to produce two of the most popular and structurally distinct metal roofing profiles: classic Corrugated metal roof sheets and robust Trapezoidal metal roof panels. While operating one profile at a time, this sophisticated metal roof sheet making machine line offers manufacturers exceptional flexibility within a single, streamlined setup, enabling swift adaptation to project requirements and market trends.

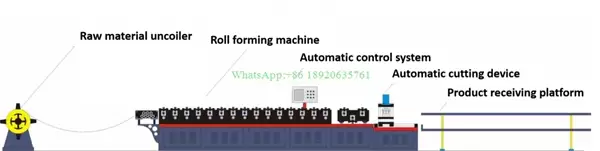

Roll Forming Process Workflow Diagram

More parameters

| Product Name | Full-automatic metal roof sheet making machine line |

| Main motor power | 7.5 kw |

| Hydraulic station | 4 kw |

| Produce speed | 12-15 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12MoV, heat treatment HRC58-62℃ |

| Roller diameter | Φ70 mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 0.3-0.8 mm |

| Rows | 13+26 |

Strategic Advantages of the Dual-Profile Metal Roof Sheet Making Machine Line:

Enhanced Market Responsiveness: Rapidly switch production between highly popular Corrugated metal roof (often favored for traditional aesthetics and cost-effectiveness) and Trapezoidal metal roof (valued for superior strength, span capability, and modern appearance) based on specific orders or market demand.

Optimized Capital Expenditure: Achieve the production capability for two major roofing product lines with the investment in a single, integrated metal roof sheet making machine line, avoiding the substantial cost of two separate dedicated lines.

Superior Space Utilization: Maximize valuable factory floor space by consolidating production for both profiles into one footprint.

Inventory Management Flexibility: Produce either Corrugated metal roof or Trapezoidal metal roof sheets on demand, reducing the need for large inventories of finished goods and allowing for just-in-time manufacturing.

High Operational Efficiency: When producing a specific profile, the metal roof sheet making machine line operates at its optimal, designed speed and efficiency for that product, maximizing output.

Reduced Changeover Impact: Advanced design features like quick-change cassettes or CNC adjustments minimize downtime when transitioning between Corrugated metal roof and Trapezoidal metal roof production, enhancing Overall Equipment Effectiveness.

The specialized metal roof sheet making machine line capable of producing both Corrugated metal roof and Trapezoidal metal roof profiles represents a significant advancement in manufacturing agility. By seamlessly integrating core processing stages with advanced, switchable roll forming technology and streamlined changeover systems, this line delivers the precision, speed, and quality essential for both classic and modern roofing solutions. Its sequential operation ensures dedicated efficiency for each profile, while its inherent dual-capability provides manufacturers with a powerful strategic asset to navigate diverse customer requirements and market fluctuations. As the demand for versatile, high-performance metal roofing continues to expand globally, this sophisticated metal roof sheet making machine line stands as an indispensable tool for manufacturers committed to innovation, efficiency, and competitive leadership in the roofing industry. Continuous improvements focus on further accelerating changeovers and enhancing the intelligence of the metal roof sheet making machine line.

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a metal roof sheet making machine line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the metal roof sheet making machine line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.