Product

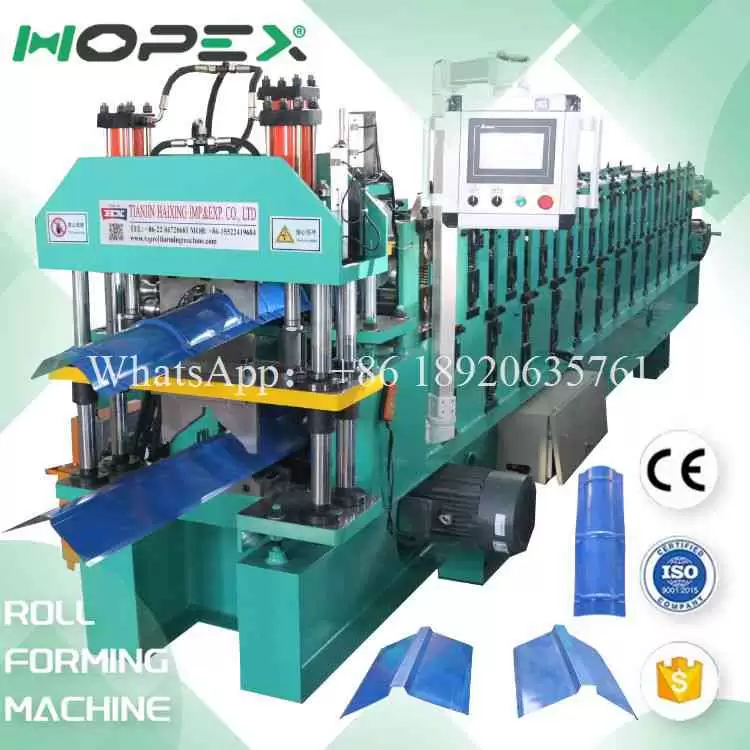

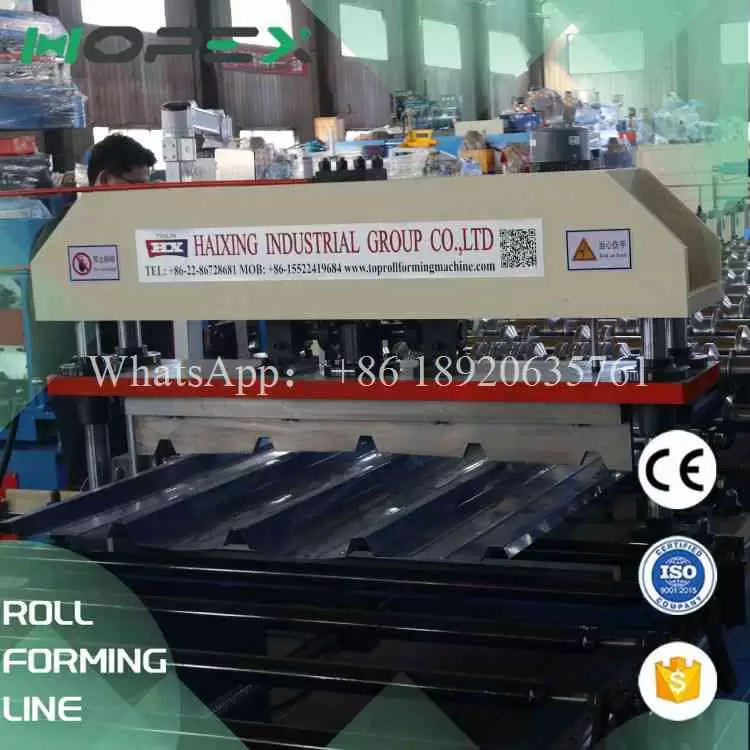

Trapezoidal Corrugated Double-Layer Roll Forming Line Machine

Dual-Profile Powerhouse: The Trapezoidal Corrugated Double-Layer Roll Forming Line Machine

For 28 years, we've engineered solutions that redefine manufacturing efficiency. Addressing the diverse demands of the roofing industry, we present the revolutionary Trapezoidal Corrugated Double-Layer Roll Forming Line Machine. This vertically integrated, PLC-controlled powerhouse enables manufacturers to produce robust trapezoidal roof panels on the upper level and classic corrugated roof/wall sheets on the lower level – all within a single, compact footprint. While operating one layer at a time, this unique roll forming line machine delivers unparalleled versatility and rapid changeover capabilities, eliminating the downtime typically associated with switching between these fundamentally different profiles. Experience the future of flexible metal roofing production.

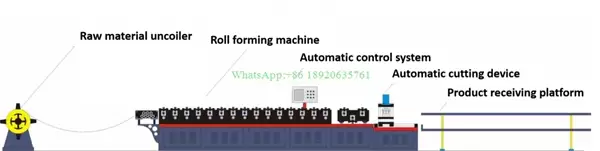

Roll Forming Process Workflow Diagram

More parameters

| Product Name |

Trapezoidal Corrugated Double-Layer Roll Forming Line Machine |

| Main motor power | 7.5 kw |

| Hydraulic station | 5.5 kw |

| Produce speed | 20 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12MoV, heat treatment HRC58-62℃ |

| Roller diameter | Φ70 mm |

| Voltage | 220v 60hz 3p be customized |

| Feeding thickness | Corrugation 0.2-0.5mm Trapezoidal 0.3-0.8mm |

| Rows | 15+20 |

Roll Forming Line Machine Operation: Efficient Workflow & Instant Profile Switching

Uncoiling and feeding: The uncoiling machine on the active layer feeds the coils steadily into the line. A centering system ensures coil alignment.

Precision leveling: The material passes through a dedicated multi-roller leveler on the active layer, which eliminates coil deformations and internal stresses, resulting in a perfectly flat sheet - essential for consistent forming quality for both profiles.

Roll forming (active layer): The prepared strip enters the heart of the roll forming line - a dedicated forming section.

Upper layer (trapezoidal): The material passes through a series of precisely designed forming roller stands. Each roller stand gradually bends the metal, gradually forming the typical trapezoidal ribs with sharp angles, specific heights and uniform spacing. The final calibration roller stand ensures perfect dimensions and sheet straightness.

Lower layer (corrugation): The material passes through a set of different forming roller stands designed for sinusoidal corrugation. These stands gently and gradually form uniformly rounded corrugations. The number of stands ensures smooth corrugations without material deformation.

Precision Cutting (Active Layer): Fully formed continuous sheets move to a high-precision flying shear on this layer. The flying shear is perfectly synchronized with the line speed and enables clean, burr-free cuts to preset lengths (e.g. 2 meters to more than 12 meters). Cutting accuracy is essential for waterproofing installation and minimizing on-site waste.

Output and Palletizing: The cut sheets move along the discharge table of the active layer. The palletizer automatically stacks the finished trapezoidal sheets or corrugated sheets neatly for efficient handling and transportation.

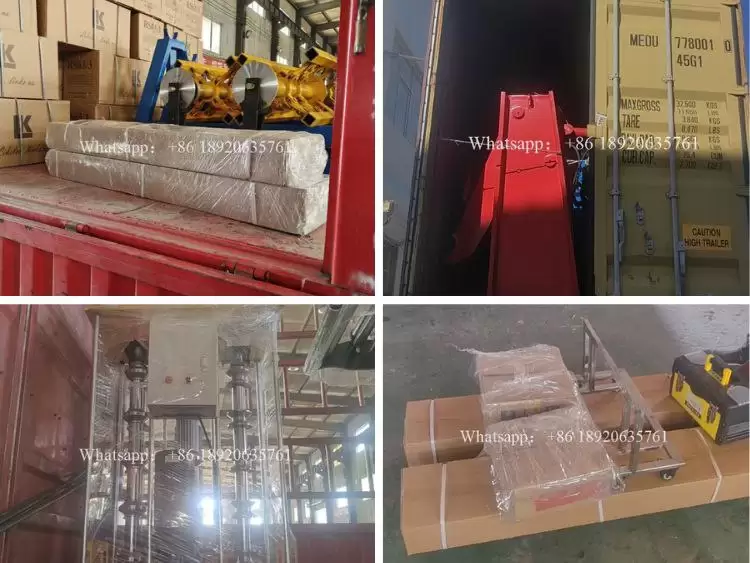

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Trapezoidal Corrugated Double-Layer Roll Forming Line Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Trapezoidal Corrugated Double-Layer Roll Forming Line Machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.