Product

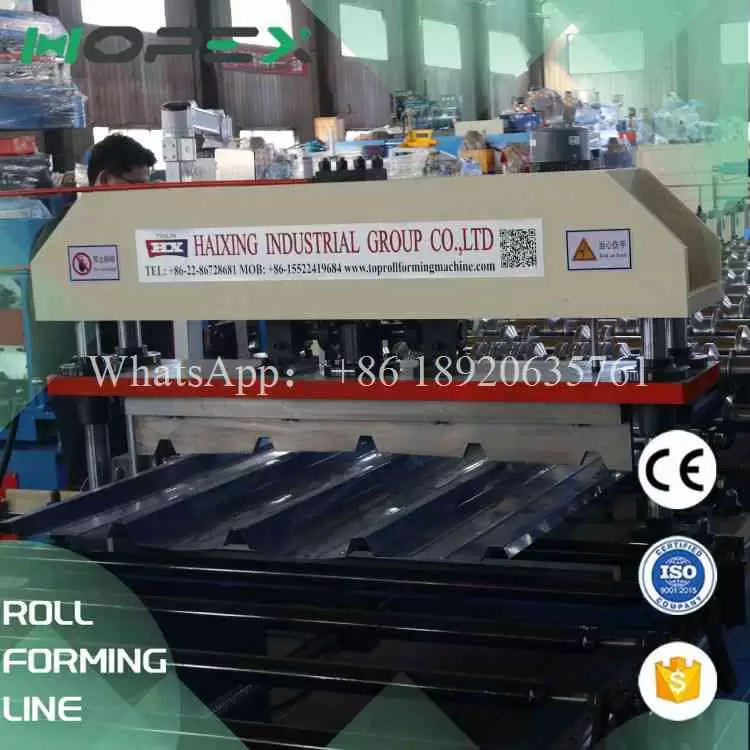

corrugated trapezoidal double-layer automatic roll forming lines

The Corrugated Trapezoidal Double-Layer Automatic Roll Forming Lines: Ultimate Flexibility for Diverse Roofing Production

In the dynamic metal roofing industry, meeting diverse architectural and structural demands requires unparalleled manufacturing agility. The Corrugated Trapezoidal Double-Layer Automatic Roll Forming Line stands as a pinnacle of engineering innovation, designed specifically to produce two highly popular yet distinct roof panel profiles – trapezoidal and corrugated – within a single, space-efficient footprint. This sophisticated automatic roll forming lines solution eliminates the costly downtime associated with retooling traditional single-profile machines, empowering manufacturers to swiftly switch between product lines and cater to a broader market with exceptional efficiency. The integration of advanced automation defines these automatic roll forming lines, ensuring precision, repeatability, and minimal operator intervention.

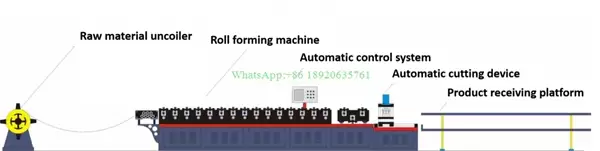

Roll Forming Process Workflow Diagram

More parameters

| Product Name |

corrugated trapezoidal double-layer automatic roll forming lines |

| Main motor power | 5.5 kw |

| Hydraulic station | 4 kw |

| Produce speed | 10-15 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-60℃ |

| Cutting blade material | Cr12MoV, heat treatment HRC58-60℃ |

| Roller diameter | Φ70 mm |

| Voltage | 220v 60hz 3p be customized |

| Feeding thickness | 0.3-0.8mm |

| Rows | 15+13 |

Machine Operation & Automated Workflow:

Profile Selection & Setup: The operator selects the desired profile (Corrugated - Upper or Trapezoidal - Lower) via the HMI. The corresponding automatic roll forming lines station is activated. The appropriate coil material is loaded onto the decoiler.

Material Preparation: The coil strip is fed automatically through the leveler, ensuring perfect flatness critical for the precision of the automatic roll forming lines.

Automated Forming: The material enters the active automatic roll forming lines station. Within this station, a progressive series of computer-designed forming rolls gradually cold-shapes the flat strip. For the lower station, this creates the sharp angles and flats of the trapezoidal profile. For the upper station, it forms the smooth, continuous curves of the corrugated profile. The automatic roll forming lines process ensures consistent cross-section geometry and minimal material stress.

Precision Cutting: As the fully formed panel exits the automatic roll forming lines station, high-resolution encoders monitor its movement continuously. This real-time data synchronizes the servo-driven flying cutoff press, which delivers pinpoint-accurate, burr-free cuts to exact pre-programmed lengths without halting the automatic roll forming lines.

Output Handling: Cut panels are automatically conveyed away, typically directed to stacking tables or packaging systems.

Switching Profiles: To change production, the operator simply halts the current automatic roll forming lines station, selects the other profile on the HMI, loads the appropriate coil, and initiates the new run. Crucially, the forming rolls for the inactive profile remain preset and ready within their dedicated automatic roll forming lines station, reducing changeover time to a fraction of that required for a traditional machine retool.

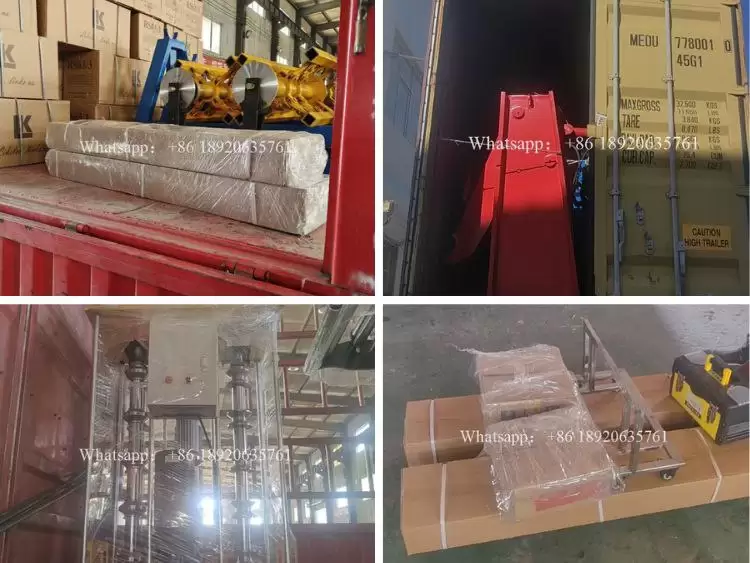

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the c. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the corrugated trapezoidal double-layer automatic roll forming lines be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.