Product

Roll Forming Machine Line

Double Layer Roof Roll Forming Machine Line: Revolutionizing Efficiency in Profile Production

For over 28 years, our company has stood at the forefront of mechanical innovation, designing and manufacturing robust solutions for the construction and building materials industries. Among our flagship offerings, the Double Layer Roof Roll Forming Machine Line represents a pinnacle of efficiency and productivity. This sophisticated roll forming machine line is engineered to transform raw coil steel into high-quality double-layer roof or wall panels with unparalleled speed and precision, fundamentally optimizing your production workflow.

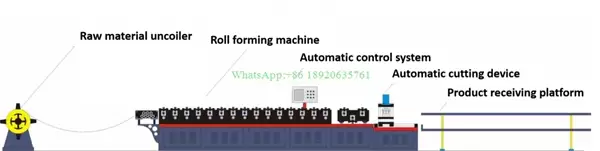

Roll Forming Process Workflow Diagram

More parameters

| Product Name | Advanced Roll Forming Machine Line for Metal Profiles |

| Main motor power | 5.5 kw |

| Hydraulic station | 4 kw |

| Produce speed | 10-15 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12MoV, heat treatment HRC58-62℃ |

| Roller diameter | Φ70 mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 0.3-0.8 mm |

| Rows | 15+15 |

Optimized workflow

Loading and uncoiling: Large steel coils are loaded onto the uncoiler.

Material preparation: The strip is fed into the straightener and straightened to make it flat and uniform.

Roll-forming: The prepared strip enters the roll-forming machine and is gradually rolled to form a continuous, perfectly formed stream of profiles, which are rolled into the predetermined shape.

Synchronized cutting: The flying shear tracks the moving profile and cuts the two layers of profiles precisely and synchronously according to the set length.

Automatic handling and stacking: The cut sheets are transported to the stacking station and automatically stacked there.

Tangible Benefits: Why Choose a Double Layer Roll Forming Machine Line?

Reduced Labor Costs: Automation, especially in stacking, and the single-line operation for double output significantly lower manpower requirements per ton of finished product.

Optimized Floor Space: Producing two layers vertically utilizes factory height more efficiently than two separate single lines side-by-side, saving valuable floor space.

Consistent Quality: Precision engineering throughout the roll forming machine line ensures identical, high-quality profiles from both layers, batch after batch.

Enhanced ROI: The combination of doubled output, lower labor costs, and space savings translates into a significantly faster return on investment for this advanced roll forming machine line compared to traditional setups.

Our photos with our customers

About us

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a double layer roof roll forming machine line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the double layer roof roll forming machine line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.