Product

Double Layer Forming Machine

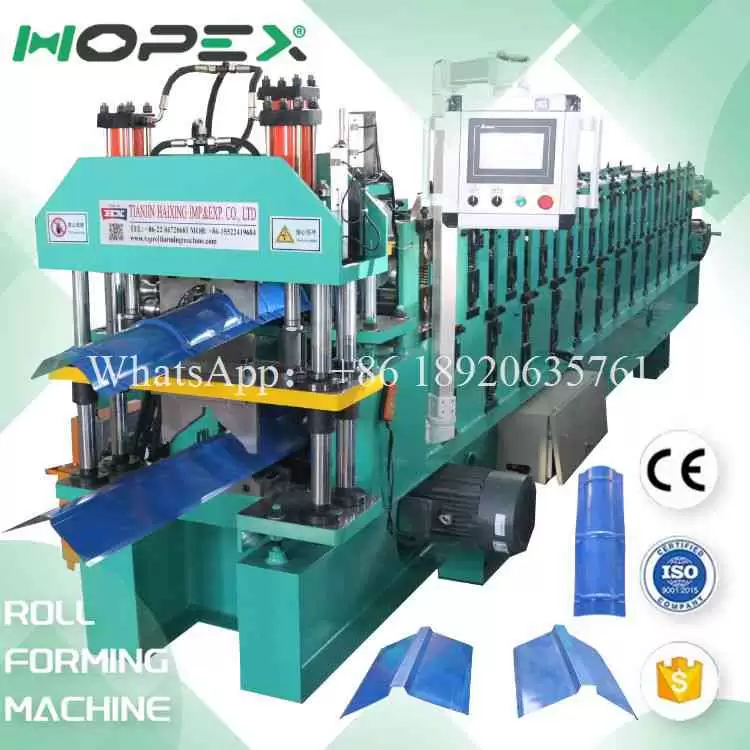

Revolutionizing Roofing Production with Our Advanced Double Layer Forming Machine

The roofing industry continues to evolve with increasing demands for efficient, versatile, and high-quality production solutions. Modern construction projects require reliable roofing components that combine durability with aesthetic appeal. As an innovative manufacturer of cold roll forming equipment, we are proud to introduce our groundbreaking Double Layer Forming Machine, a sophisticated production line that represents a significant advancement in roofing manufacturing technology. This unique system is engineered to simultaneously produce two different roofing profiles, dramatically enhancing production efficiency while optimizing factory space utilization.

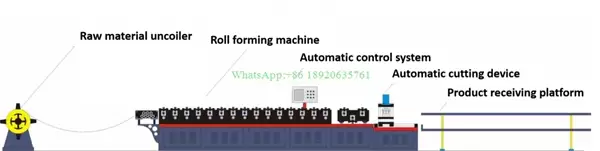

Roll Forming Process Workflow Diagram

More parameters

| Product Name | Double Layer Forming Machine |

| Main motor power | 5.5 kw |

| Hydraulic station | 5.5 kw |

| Produce speed | 10-15 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | 45# Steel |

| Cutting blade material | Cr12MoV, heat treatment HRC58-62℃ |

| Roller diameter | Φ70 mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 0.25-0.8 mm |

| Rows | 14+13 |

Our Double Layer Forming Machine features an ingenious dual-level design that sets it apart from conventional single-profile production lines. The upper level of this advanced Double Layer Forming Machine is dedicated to manufacturing high-quality corrugated roof panels, known for their classic wave-like pattern and excellent water-shedding capabilities. Simultaneously, the lower level of this innovative Double Layer Forming Machine produces trapezoidal roof panels, valued for their superior structural strength and modern appearance. This dual-production capability allows manufacturers to efficiently produce two distinct roofing profiles within the same footprint, effectively doubling output without increasing factory space requirements.

The production process of our Double Layer Forming Machine incorporates a streamlined, automated workflow that ensures consistent quality for both roofing profiles. The system begins with two independent decoiling units that feed steel coils into their respective production levels with precise tension control. The material then proceeds to the precision roll forming sections, where computer-engineered rollers gradually shape the flat steel strips into the desired corrugated and trapezoidal profiles. Following the forming stages, high-speed flying shears accurately cut both continuous profiles to required lengths without interrupting production flow. The automated process concludes with stacking devices that neatly organize the finished roofing panels for convenient handling and shipment.

A key advantage of our Double Layer Forming Machine is its remarkable flexibility and customization capability. Manufacturers can adjust various parameters including material width, thickness, and profile dimensions for both production levels according to specific project requirements. This adaptability ensures that production can quickly respond to changing market demands and customer preferences. To support rapid project implementation, we provide an efficient 3-day drawing approval service. Our engineering team delivers detailed technical schematics and layout plans for client review, ensuring the production configuration meets all specifications before manufacturing begins.

Beyond the advanced machinery, we offer comprehensive technical support to ensure optimal performance. Our remote service program includes real-time video guidance from experienced engineers, who provide assistance with machine installation, operational training, and troubleshooting through digital platforms. This remote support ensures that your Double Layer Forming Machine maintains peak performance while minimizing potential downtime.

Investing in our Double Layer Forming Machine represents a strategic commitment to manufacturing excellence and operational efficiency. This innovative production solution enables roofing manufacturers to diversify their product offerings, increase production capacity, and enhance market competitiveness. By integrating this advanced technology into their operations, manufacturers can effectively meet the growing demands of the construction industry while maintaining the highest standards of quality and precision in roofing panel production.

OUR CERTIFICATE

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Double Layer Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Double Layer Forming Machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.