Product

Professional special shape purlin machine line

Special Shape Purlin Machine Line: Tailored Roll Forming for Complex Structural Profiles

The Special shape purlin machine line is an advanced and versatile roll forming solution designed to manufacture non-standard purlin profiles that meet unique structural and architectural requirements. Unlike conventional purlin lines that focus on common shapes like C, Z, or Omega, the Special shape purlin machine line is engineered to produce customized cross-sections tailored for specialized applications in steel buildings, modular construction, and infrastructure projects. With its precision forming capabilities and adaptable design, this machine line addresses the growing demand for innovative, high-performance building components.

As industries move toward more complex and lightweight steel structures, the role of uniquely designed purlins becomes increasingly critical. The Special shape purlin machine line provides manufacturers with the flexibility to design and produce structural elements that offer both functional and aesthetic advantages. From highly contoured purlins with reinforcing ribs to hybrid profiles with multiple bends, this machine makes it possible to meet even the most demanding project specifications.

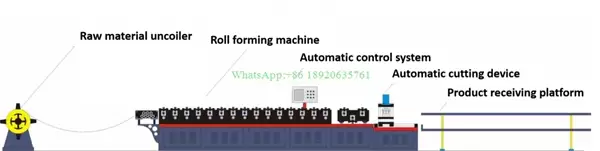

Roll Forming Process Workflow Diagram

More parameters

| Product Name | |

| Main motor power | 15 kw |

| Hydraulic station | 7.5 kw |

| Produce speed | 25 m/min |

| Shaft material | 45# Steel |

| Touch screen | Delta or customized according to customer requirements |

| Rolling materials | Cr15 |

| Cutting blade material | SKD11 heat treatment |

| Roller diameter | Φ70 mm |

| Voltage | 220v 60hz 3p be customized |

| Feeding thickness |

0.8-2.0 mm |

| Rows | 15 |

Key Features of the Special Shape Purlin Machine Line

Profile Customization: Capable of producing a wide range of unique and complex profiles based on customer drawings or engineering designs.

Modular Roller Design: The roller stations can be adjusted or replaced to accommodate different shapes and dimensions with minimal downtime.

High-Precision Forming: Advanced alignment systems and fine-tuned roller setups ensure perfect geometry and tight dimensional tolerances.

PLC-Controlled Operation: Automated control systems with user-friendly interfaces allow easy parameter setting, profile programming, and real-time monitoring.

Durable and Low-Maintenance Structure: The machine frame is constructed with heavy-duty welded steel, and the moving parts are made from wear-resistant materials to ensure long service life.

Energy Efficiency: Equipped with energy-saving drives and motors, the line is optimized for low energy consumption without compromising performance.

Benefits of the Special Shape Purlin Machine Line

Choosing the Special shape purlin machine line offers numerous advantages to manufacturers and construction professionals:

Design Freedom: Engineers are no longer restricted to standard purlin shapes. With this machine, they can implement structural profiles optimized for specific loads, spans, or aesthetic requirements.

Production Flexibility: The machine supports quick changeovers and can handle diverse production runs, from prototypes to high-volume batches.

Consistent Quality: Automated forming and cutting processes ensure consistent product quality, which is critical for structural safety and performance.

Reduced Material Waste: Precision cutting and efficient forming minimize material loss, resulting in cost savings and a more sustainable production process.

Faster Project Turnaround: On-demand production of custom purlins shortens lead times for construction projects that require non-standard components.

Application Areas of Special Shape Purlins

The special purlins manufactured by the Special shape purlin machine line are widely used in projects that demand more than conventional structural solutions:

Industrial Buildings: Custom purlins used in high-bay warehouses, factories, and logistics centers.

Architectural Facades: Non-linear or designer purlins used as part of curtain wall systems or exterior support frames.

Solar Mounting Structures: Special profiles used to optimize load-bearing capacity and installation efficiency for photovoltaic panels.

Transportation Infrastructure: Purlins for support structures in bridges, rail stations, and airports.

Light Steel Framing Systems: Custom components for modular housing, portable buildings, or steel villas.

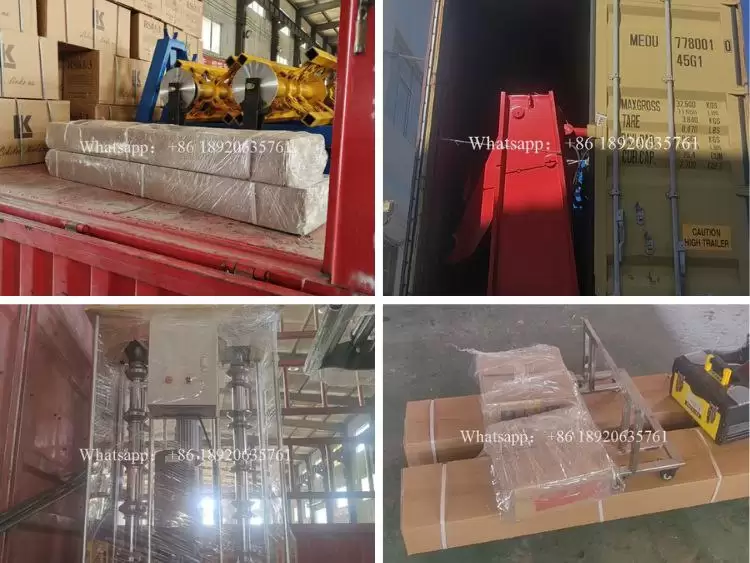

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the Special shape purlin machine line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the automatic Special shape purlin machine line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.