Product

Omega Purlin Roll Forming Machine Line

Omega Purlin Roll Forming Machine Line: A Comprehensive Overview

The Omega Purlin Roll Forming Machine Line is a cutting-edge piece of equipment designed to produce high-quality Omega-shaped purlins used in various construction applications. These purlins play a crucial role in the construction of roofs, warehouses, factories, and other steel-structured buildings. With its advanced technology, the Omega Purlin Roll Forming Machine Line ensures the efficient production of these structural components, making it an essential tool in modern construction industries.

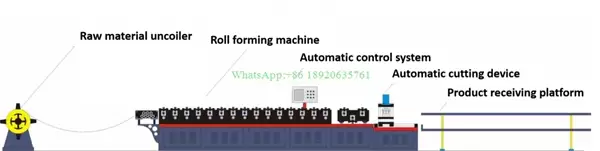

Roll Forming Process Workflow Diagram

More parameters

| Product Name | |

| Main motor power | 15 kw |

| Hydraulic station | 7.5 kw |

| Produce speed | 25 m/min |

| Shaft material | 45# Steel |

| Touch screen | Delta or customized according to customer requirements |

| Rolling materials | Cr15 |

| Cutting blade material | SKD11 heat treatment |

| Roller diameter | Φ70 mm |

| Voltage | 220v 60hz 3p be customized |

| Feeding thickness |

0.8-2.0 mm |

| Rows | 15 |

Introduction to Omega Purlin Roll Forming Machine Line

The Omega Purlin Roll Forming Machine Line is specifically designed to form cold-rolled steel sheets into Omega-shaped purlins. This machine line is widely used for producing structural steel components that provide support to roofs and walls in large industrial buildings. The machine's ability to create purlins with precision and consistency makes it a preferred choice for manufacturers and builders alike. The purlins produced by this machine are versatile, durable, and can be used in various applications, from residential to commercial construction.

Key Features of Omega Purlin Roll Forming Machine Line

The Omega Purlin Roll Forming Machine Line comes equipped with several key features that ensure its efficiency and reliability. These include:

High Precision and Consistency: The machine uses advanced roll forming technology, which guarantees that every purlin produced is consistent in shape and dimension.

Flexible Production: The line can produce purlins of different sizes and thicknesses, making it highly versatile. Manufacturers can easily adjust the machine to accommodate various production needs.

Automated Process: The Omega purlin machine operates in an automated manner, reducing the need for manual labor and minimizing the risk of human error.

High-Speed Operation: The machine is capable of high-speed production, allowing manufacturers to meet large-scale production demands without compromising on quality.

Durability and Low Maintenance: The Omega Purlin Roll Forming Machine Line is built with high-quality materials, ensuring durability and longevity. It requires minimal maintenance, which reduces downtime and operational costs.

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the Omega Purlin Roll Forming Machine Line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the automatic Omega Purlin Roll Forming Machine Line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.