Product

Full-production CZ purlin roll forming machine Line

CZ Purlin Roll Forming Machine Line: Engineering Excellence for Structural Framing Components

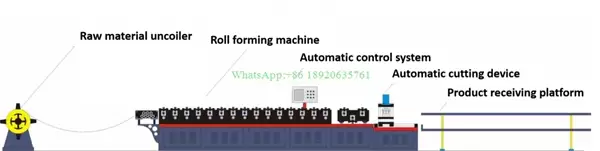

In the demanding world of construction and pre-engineered buildings (PEBs), the structural integrity and efficient production of load-bearing components are paramount. The CZ Purlin Roll Forming Machine Line stands as a cornerstone technology, engineered to transform raw steel coil into high-precision C and Z section purlins – the essential horizontal beams forming the skeleton of countless roofs and walls. This fully integrated, automated production system delivers unmatched efficiency, consistency, and quality, making it an indispensable asset for manufacturers supplying the global construction industry.

Roll Forming Process Workflow Diagram

More parameters

| Product Name | |

| Main motor power | 15 kw |

| Hydraulic station | 7.5 kw |

| Produce speed | 25 m/min |

| Shaft material | 45# Steel |

| Touch screen | Delta or customized according to customer requirements |

| Rolling materials | Cr15 |

| Cutting blade material | SKD11 heat treatment |

| Roller diameter | Φ70 mm |

| Voltage | 220v 60hz 3p be customized |

| Feeding thickness |

0.8-2.0 mm |

| Rows | 15 |

Why Invest in a CZ Purlin Roll Forming Machine Line?

The benefits translate directly into competitive advantage:

Massive Productivity: Continuous operation, high forming speeds (often 22 meters per minute), and minimized downtime enable exceptionally high output volumes, meeting the demands of large-scale construction projects.

Uncompromising Quality & Consistency: Precision leveling, servo-controlled forming, and hydraulic cutting guarantee every purlin meets stringent dimensional tolerances and geometric accuracy, batch after batch. This consistency is vital for structural performance and on-site fitment.

Superior Material Yield: Optimized cutting based on precise encoder feedback, coupled with efficient coil utilization and minimized scrap from consistent forming, significantly reduces material costs.

Reduced Labor Costs & Enhanced Safety: Automation drastically reduces manual intervention, particularly in heavy lifting (coils), feeding, cutting, and stacking long purlins, lowering labor costs and significantly improving workplace safety.

Operational Flexibility: Quick tooling changeovers (roll sets) between C and Z profiles or different sizes allow manufacturers to respond swiftly to diverse customer orders. Servo systems further enhance flexibility for custom profiles or variable dimensions.

Robust Construction & Reliability: Built for demanding industrial environments with high-quality components (hardened rolls, heavy-duty frames, reliable hydraulics, industrial-grade controls), ensuring long-term durability and minimal maintenance downtime.

Data Integration & Monitoring: Modern CZ Purlin Roll Forming Machine Line systems offer comprehensive data logging (OEE, production counts, fault diagnostics, material usage) for real-time monitoring, performance analysis, predictive maintenance, and optimized production planning.

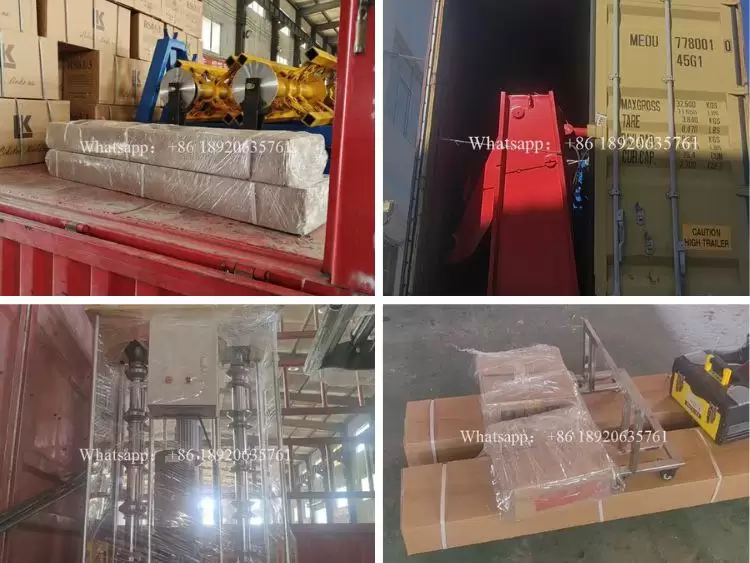

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the cz purlin roll forming machine for sale. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the automatic cz purlin roll forming machine for sale be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.