Product

Cable Tray Production Line

Comprehensive Solution with Advanced Cable Tray Production Line

As a professional manufacturer of roll forming equipment, we are proud to introduce our complete cable tray production line, designed to revolutionize your manufacturing process. This integrated cable tray production line combines advanced technology with robust engineering to deliver unmatched efficiency and precision in cable tray manufacturing. The system performs all essential processes in one continuous operation, from raw material to finished product.

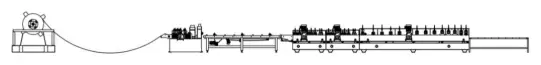

Workflow Diagram

Our cable tray production line begins with a heavy-duty decoiling system that ensures smooth material feeding. The metal then passes through a precision leveling unit that eliminates any imperfections and ensures perfect flatness. The leveled material undergoes hydraulic shearing for accurate length cutting and proceeds to the punching station, where custom hole patterns and shapes are created according to specific requirements. Finally, the roll forming section shapes the prepared material into perfect cable tray profiles through a series of precisely engineered forming rollers.

The cable tray production line offers complete customization capabilities, allowing manufacturers to adjust various parameters including profile designs, hole patterns, material widths, and thicknesses. This flexibility enables production of both standard and custom-designed cable trays to meet diverse market demands. Our engineering team provides comprehensive support with technical drawings within three days and remote video guidance for operation and maintenance.

What sets our cable tray production line apart is its exceptional automation level and reliability. The system significantly reduces labor requirements while maintaining consistent product quality and dimensional accuracy. The cable tray production line is designed for continuous operation, minimizing downtime and maximizing productivity. Our remote technical support ensures prompt assistance and troubleshooting, guaranteeing optimal performance of your cable tray production line.

Investing in our cable tray production line means investing in quality, efficiency, and innovation. This complete solution enables manufacturers to enhance their production capacity, reduce operational costs, and improve product quality. The cable tray production line represents our commitment to providing cutting-edge manufacturing solutions that help our clients stay competitive in the global market.

We invite you to experience the superior performance of our cable tray production line. Contact us today to learn how this advanced system can transform your manufacturing process and help you achieve new levels of production excellence. Our team is ready to provide detailed information and demonstrate how our cable tray production line can meet your specific manufacturing requirements.

More parameters

| Product Name | Cable Tray Production Line |

| Material rack | Hydraulic core expansion Electric unwinding function Inner diameter expansion and contraction range: φ460-520 mm Maximum coil outer diameter: φ1500 mm Load capacity: 6 tons |

| Roll forming the second half | Opposing Roll Forming Main Motor Power (5.5 kW) Opening and Closing Motor Power (1.5 kW) |

| Main motor power | 7.5 kw |

| Hydraulic components | 11 KW |

| Cutting type | Hydraulic shear |

| Produce speed | 8-16m/min |

| Small edge roll forming part | Inward-turning small edge: 6-row roll forming Small edge leveling Main motor power (5.5 kW) Opening and closing servo motor power (1.5 kW) Outward-turning small edge: 6-row roll forming Small edge leveling Main motor power (5.5 kW) Opening and closing servo motor power (1.5 kW) |

| Brand of electrical control cabinet | Delta or customized according to customer requirements |

| Touch screen/inverter | Delta or customized according to customer requirements |

| High-speed platform | 3m roller feed table (1 unit) Main motor power (1.5kW) Electric opening and closing |

| Forming size | 400/100, 400/50, 300/100, 300/50, 200/100, 200/50, 100/100, 100/50, 50/50 |

| Rolled strip thickness | 0.8(±0.03)-1.5 (±0.03) mm |

| Voltage | 400V±5%,60Hz,3p, be customized |

| Feeding thickness | 0.8-1.5 mm |

| Rows | 26 |

| Equipment footprint | 30×2.5×2.2 m |

| Feeding width | 200-650mm(200-800) |

Our commitment to your success extends far beyond the factory floor and the initial sale. We provide comprehensive remote support to ensure your Cable Tray Production Line operates at peak performance. Our experienced engineers offer remote warranty service and real-time video online guidance for operational training, routine maintenance, and troubleshooting. This dedicated after-sales support minimizes potential downtime and empowers your team to leverage the full potential of your investment.

In conclusion, our integrated Cable Tray Production Line represents the pinnacle of manufacturing efficiency and versatility. It is a turnkey solution designed to reduce labor costs, minimize material waste, and produce superior quality cable trays that meet the most stringent international standards. By investing in our Cable Tray Production Line, you are not just purchasing machinery; you are forging a partnership dedicated to driving your business growth. Contact us today to discuss your project and discover how our Cable Tray Production Line can be configured to elevate your manufacturing capabilities to new heights.

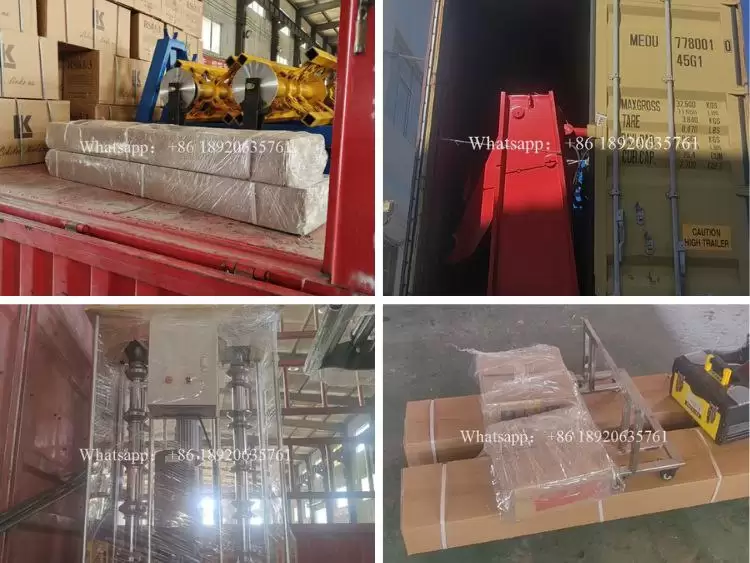

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

Transportation and delivery