Product

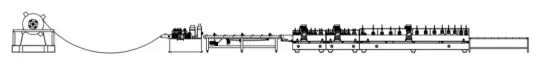

Cable Tray Forming Machine

Innovate Your Production with Our Advanced Cable Tray Forming Machine

In the rapidly evolving world of electrical infrastructure and industrial construction, the demand for high-quality cable management solutions has never been greater. As a leading manufacturer of roll forming equipment, we take pride in introducing our state-of-the-art cable tray forming machine, engineered to deliver exceptional performance, precision, and versatility. This robust system is designed to streamline your manufacturing process, reduce operational costs, and produce cable trays that meet the highest industry standards. Our cable tray forming machine integrates multiple critical processes into one seamless, automated production line, ensuring efficiency from raw material to finished product.

Workflow Diagram

The production journey begins with an automated decoiling unit, which handles heavy coils of steel, aluminum, or other metals with consistent reliability. This initial stage is vital for maintaining a smooth and uninterrupted flow of material into the system. The material then moves to a precision leveling machine, where any internal stresses, curls, or imperfections from the coiling process are eliminated. This step ensures the material is perfectly flat and uniform, which is essential for achieving the dimensional accuracy and superior surface quality of the final cable trays. Without proper leveling, the end product would lack the structural integrity and professional appearance required for critical applications.

Next, the flat material is fed into a hydraulic punching station. This is where the flexibility of our cable tray forming machine truly stands out. Custom hole patterns, ventilation louvers, mounting slots, and other specific perforations can be punched into the material with remarkable accuracy. The tooling and programming can be quickly adjusted to accommodate different designs, making the machine ideal for both high-volume production runs and customized orders. This versatility allows manufacturers to respond swiftly to varying client requirements without sacrificing efficiency or quality.

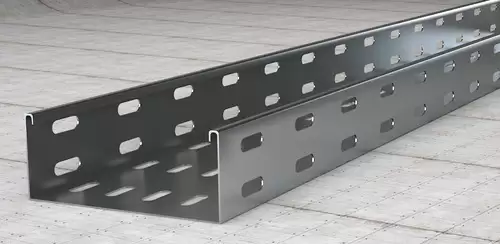

The heart of the system is the roll forming section, where the flat sheet is gradually shaped into the desired cable tray profile. Through a series of meticulously engineered forming stands, the metal is cold-worked into configurations such as ladder-type, trough-type, or other custom designs. The cold-forming process not only maintains but enhances the material's strength, ensuring the final product is both durable and reliable. Our cable tray forming machine supports extensive customization, including material width and thickness, profile design, and punching patterns, ensuring that every client receives a solution tailored to their specific needs.

More parameters

| Product Name | Cable Tray Making Machine Production Line |

| Material rack | Hydraulic core expansion Electric unwinding function Inner diameter expansion and contraction range: φ460-520 mm Maximum coil outer diameter: φ1500 mm Load capacity: 6 tons |

| Roll forming the second half | Opposing Roll Forming Main Motor Power (5.5 kW) Opening and Closing Motor Power (1.5 kW) |

| Main motor power | 7.5 kw |

| Hydraulic components | 11 KW |

| Cutting type | Hydraulic shear |

| Produce speed | 8-16m/min |

| Small edge roll forming part | Inward-turning small edge: 6-row roll forming Small edge leveling Main motor power (5.5 kW) Opening and closing servo motor power (1.5 kW) Outward-turning small edge: 6-row roll forming Small edge leveling Main motor power (5.5 kW) Opening and closing servo motor power (1.5 kW) |

| Brand of electrical control cabinet | Delta or customized according to customer requirements |

| Touch screen/inverter | Delta or customized according to customer requirements |

| High-speed platform | 3m roller feed table (1 unit) Main motor power (1.5kW) Electric opening and closing |

| Forming size | 400/100, 400/50, 300/100, 300/50, 200/100, 200/50, 100/100, 100/50, 50/50 |

| Rolled strip thickness | 0.8(±0.03)-1.5 (±0.03) mm |

| Voltage | 400V±5%,60Hz,3p, be customized |

| Feeding thickness | 0.8-1.5 mm |

| Rows | 26 |

| Equipment footprint | 30×2.5×2.2 m |

| Feeding width | 200-650mm(200-800) |

We understand that every manufacturer has unique requirements, which is why our engineering team works closely with clients to develop optimal configurations. We are committed to rapid turnaround times, providing detailed production drawings within just three days of finalizing specifications.

Our support extends far beyond the initial purchase and installation. We offer comprehensive remote services, including video online guidance and real-time troubleshooting, ensuring that your team can operate the cable tray forming machine with confidence and efficiency. Our engineers are available for virtual assistance, providing expert advice on maintenance, operational best practices, and minor adjustments to keep your production line running smoothly.

In summary, our cable tray forming machine represents the perfect blend of innovation, reliability, and adaptability. It is an ideal investment for manufacturers seeking to enhance their capabilities, improve product quality, and expand their market reach. By choosing our cable tray forming machine, you are not only acquiring advanced machinery but also partnering with a team dedicated to your long-term success. Contact us today to learn more about how our cable tray forming machine can transform your production process and drive your business forward.

Application Scenario

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.