Product

Solar Bracket Roll Forming Machine Production Line

Maximize Your Solar Energy Projects with Our Advanced Solar Bracket Roll Forming Machine Production Line

The global shift toward renewable energy has placed solar power at the forefront of sustainable development. For manufacturers specializing in photovoltaic (PV) mounting systems, production efficiency, customization, and consistent quality are critical. Our company, a trusted manufacturer of cold roll forming machinery, is proud to introduce our fully automated Solar Bracket Roll Forming Machine Production Line. This integrated solution is specifically engineered to produce high-strength, precision-formed solar brackets with remarkable speed and accuracy, supporting the growing demands of the solar industry worldwide.

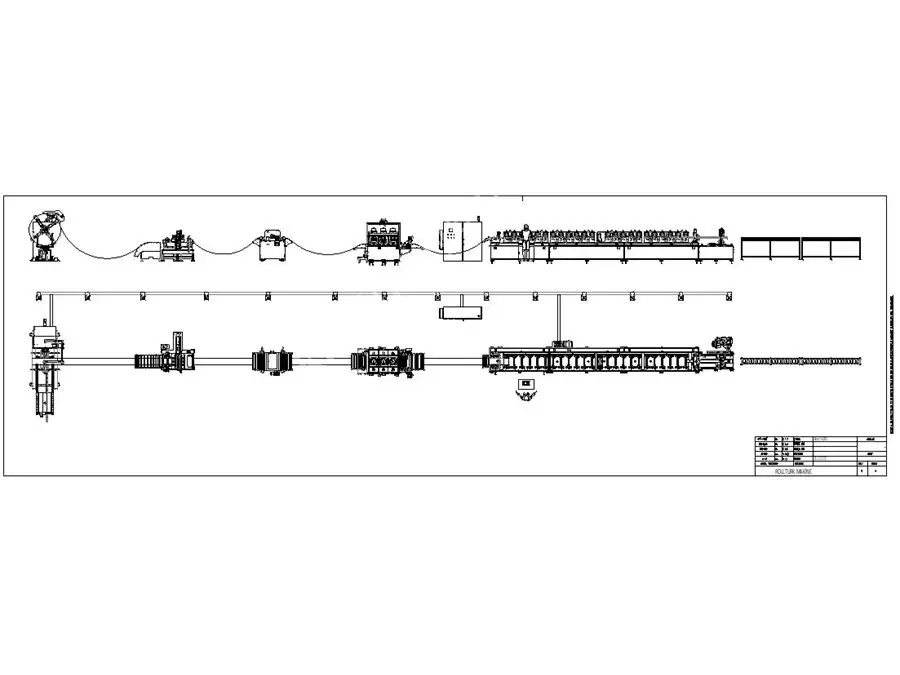

Our Solar Bracket Roll Forming Machine Production Line seamlessly integrates several key processes into one continuous, efficient operation. It begins with an automatic decoiler that feeds steel coil into the system. The material then moves through a high-precision punching unit, where holes are accurately punched for bolts and connections. A flying shear cuts the profile to the required length without stopping the forming process, ensuring high productivity. The core of the line is the robust roll forming machine, which gradually shapes the metal strip into the desired solar bracket profile with exceptional consistency. Finally, an automatic stacking device collects the finished products, ready for packaging or further assembly.

Workflow Diagram

Understanding that project specifications vary, we have designed this Solar Bracket Roll Forming Machine Production Line for maximum flexibility. Crucial parameters such as the size and position of the punching holes, as well as the material thickness handled by the roll forming mills, can be fully customized to meet your exact technical drawings and load requirements. This ensures the production of perfectly tailored solar brackets for any installation environment.

More parameters

| Product Name | Solar Bracket Roll Forming Machine Production Line |

| Punching | Servo non-stop punching |

| Structure | 500H Beam |

| Main motor power | Dual 18.5KW motors + K97 reducer |

| Hydraulic components | 11KW×2 pump station 1 unit (for punching) 4KW pump station 1 unit (for cutting) 3KW pump station 1 unit (for pressing) |

| Cutting type | Tracking Cut |

| Produce speed | 15-20 m/min |

| Shaft material | 45# steel, quenched and tempered |

| Brand of electrical control cabinet | Delta or customized according to customer requirements |

| Touch screen/inverter | Delta or customized according to customer requirements |

| Rolling materials | High quality CR12 quenching |

| Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| Roller diameter | Φ80mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 2.0-3.0mm |

| Rows | The number of rows is usually 24-26, and the 3mm thick 41*72 model may have 28 rows. |

To accelerate your time to market, we provide a rapid 3-day drawing approval service. Our engineering team delivers detailed CAD layouts and technical schematics for your confirmation, guaranteeing the system meets all specifications before manufacturing. Furthermore, we offer comprehensive remote support, including online warranty services and real-time video guidance from our engineers. This ensures smooth installation, operator training, and prompt troubleshooting for your Solar Bracket Roll Forming Machine Production Line, minimizing downtime no matter your location.

Investing in our Solar Bracket Roll Forming Machine Production Line means investing in superior productivity, unwavering quality, and long-term technical partnership. It is the ideal solution for manufacturers aiming to lead in the rapidly expanding solar energy market.

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Solar Bracket Roll Forming Machine Production Line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Solar Bracket Roll Forming Machine Production Line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.