Product

Professional cable tray making machine

Unlocking Efficiency and Precision: Your Guide to the Professional Cable Tray Making Machine

In the intricate network of modern construction, electrical infrastructure is the vital nervous system. Safely housing and organizing the countless cables powering buildings, factories, and data centers falls to a critical component: the cable tray. Producing these essential support structures efficiently, accurately, and to exacting standards requires specialized equipment. Enter the cornerstone of high-volume cable tray manufacturing: the Professional Cable Tray Making Machine. This integrated production line transforms raw metal coil into finished cable tray sections with remarkable speed and consistency, making it an indispensable asset for manufacturers aiming for quality and competitiveness.

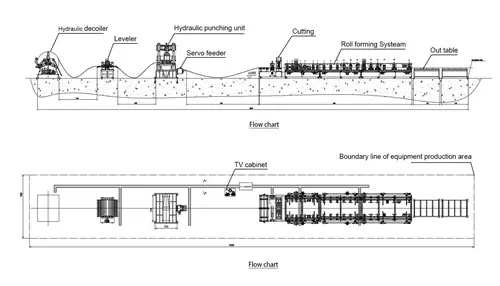

Workflow Diagram

More parameters

| Product Name | Professional cable tray making machine |

| Punching | Two-station punching machine for punching seven-shaped button holes and marking thickness 0.5-1.5 (optional) |

| Flat sheet machine roll forming part | Electric feed port 8-row roller forming Small side leveling Guide scale plate to adjust pressure Pressure spring adjustment Side reinforcement ribs and closing motor power (1.5KW) |

| Main motor power | 7.5 kw |

| Hydraulic components | Hydraulic station 2*7.5KW. Solenoid valve 220V. 3 stations |

| Cutting type | Hydraulic three-piece shear |

| Produce speed | 8-16m/min |

| Shaft material | Cr12 |

| Brand of electrical control cabinet | Delta or customized according to customer requirements |

| Touch screen/inverter | Delta or customized according to customer requirements |

| Rolling materials | High quality CR12 quenching |

| Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| Roller diameter | Φ80mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 0.5-2.5mm |

| Rows | 26 |

| Hydraulic station | Multiple solenoid valves, solenoid overflow valve, cooling system, motor power (7.5X2) KW, oil tank capacity (450) liters |

| Feeding width | 200-1250mm(200-800) |

Deconstructing the Production Flow: Core Components of a Professional Cable Tray Making Machine

The efficiency of a Professional Cable Tray Making Machine lies in the seamless integration of its key processing stations:

Uncoiling/Decoiling: The journey begins here. A heavy-duty uncoiler securely holds the master coil of steel (galvanized, pre-galvanized, stainless steel, or aluminum). Utilizing expanding mandrels and equipped with a tension control system (pneumatic brake or drive), it feeds the leading end of the coil smoothly into the line. Stability and controlled material feed are paramount for the entire Professional Cable Tray Making Machine process. Optional coil cars facilitate efficient loading of heavy coils.

Straightening/Leveling: Coiled metal inherently possesses curvature (coil set) and potential imperfections like crossbow or edge wave. Passing through a precision multi-roll leveler is crucial. These powerful rollers apply carefully calibrated bending stresses to the strip, effectively eliminating these distortions and delivering perfectly flat, uniform material to the subsequent stations. Consistent flatness is non-negotiable for achieving precise forming and punching throughout the Professional Cable Tray Making Machine.

Punching/Notching (The Mark of Identity & Function): This is often where the Professional Cable Tray Making Machine demonstrates significant sophistication. A high-tonnage punching station, synchronized with the line speed, performs critical operations:

Hole Punching: Creating the characteristic holes in ladder rungs for cable tie-downs or ventilation.

End Notching: Shaping the ends of side rails for secure joining (e.g., swaged ends).

Accessory Holes: Punching holes for mounting brackets or connecting hardware.

Part Marking: Optionally adding identification codes or logos. Modern CNC-controlled Professional Cable Tray Making Machine lines offer exceptional flexibility in punch patterns through quick-change tooling and programmable controls, allowing for easy adaptation to different tray designs.

Roll Forming/Profile Shaping (The Heart of Formation): The leveled and punched strip enters the core of the Professional Cable Tray Making Machine – the roll forming mill. Here, a series of precision-engineered contoured rollers, mounted in successive stands, progressively bend the flat metal strip into the complex cross-sectional shape of the cable tray component (e.g., the distinctive "C" or "L" shape of side rails, the rounded profile of ladder rungs). Each set of rolls adds incremental bends until the final profile emerges. The design and machining accuracy of these rolls are critical to achieving the exact dimensions, angles, and smooth finish required for cable trays that meet industry standards (like IEC 61537, NEMA VE 1, BS EN 61537). A true Professional Cable Tray Making Machine ensures consistent profile geometry along the entire length.

Cutting to Length (Precision Separation): Once the profile is fully formed, the continuous length needs to be cut into individual tray sections. A high-precision cutting system, typically a hydraulic flying shear synchronized with the moving profile, makes clean, burr-free cuts at predetermined lengths. Accuracy here is vital for ensuring uniform tray sections that assemble seamlessly on-site. Advanced Professional Cable Tray Making Machine lines feature CNC-controlled cut-off for precise length control and minimal waste.

Application Scenario

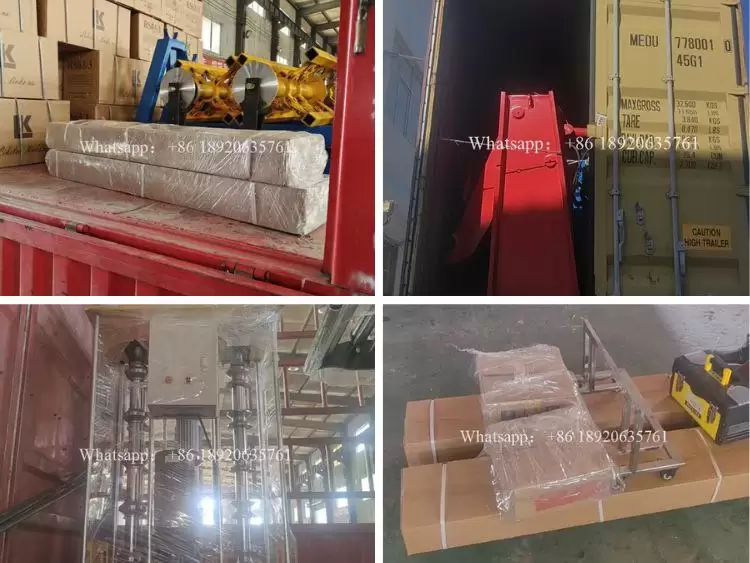

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Professional cable tray making machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Professional cable tray making machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.