Product

Z-type Light Steel Keel Roll Forming Machine - High-performance Machine

Z-type Light Steel Keel Roll Forming Machine: Customizable, Efficient Solution for Construction

As a professional cold roll forming machine manufacturer, we take pride in presenting the Z-type Light Steel Keel Roll Forming Machine — a high-performance equipment tailored to meet the evolving needs of the construction industry. This advanced Z-type Light Steel Keel Roll Forming Machine integrates precision engineering with user-centric design, delivering reliable and efficient production of Z-shaped light steel keels, which are widely used in building interiors, partitions, and roofing systems.

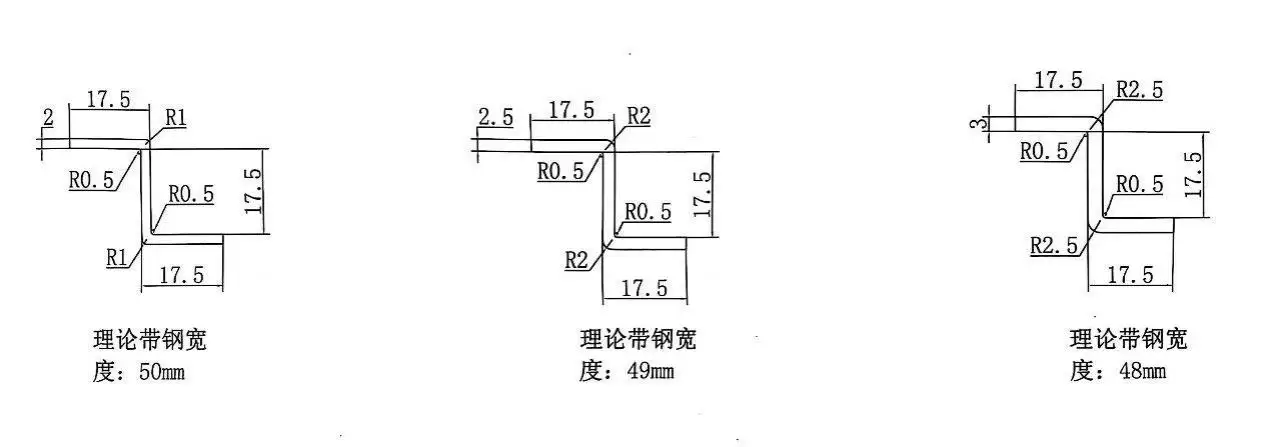

Diagram

One of the core advantages of our Z-type Light Steel Keel Roll Forming Machine is its exceptional customizability. We understand that different projects have unique requirements, so the machine allows full customization of key parameters: feed thickness, feed width, voltage, and even the display screen language. Whether you need to process thin or thick steel sheets, adjust the width to match specific keel dimensions, or set the voltage to fit local power standards, our Z-type Light Steel Keel Roll Forming Machine adapts seamlessly, eliminating compatibility issues and enhancing operational flexibility.

More parameters

| Product Name | |

| Main motor power | 30KW Siemens main motor, K series gearbox |

| Hydraulic station | 7.5KW Siemens |

| Produce speed | 30 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12 |

| Voltage | 415v 50hz 3p be customized |

| Feeding thickness |

1.5-3 mm

|

| Rows | 19th row |

| Shaft diameter | 80 mm |

| Cutting method | Hydraulic shutdown and cut-off |

| Cutting tolerance | +-1.0 mm |

| PLC display language | Chinese, English, Spanish (customizable) |

The production process of the Z-type Light Steel Keel Roll Forming Machine is streamlined and automated, covering five key stages: uncoiling, feeding, roll forming, cutting, and stacking. The uncoiling unit ensures stable material supply, while the precision feeding system guarantees uniform movement of steel sheets. The roll forming section, equipped with high-quality rollers, shapes the steel into standard Z-type keels with consistent dimensions and smooth surfaces. After forming, the automatic cutting system trims the keels to the required length accurately, and the stacking unit arranges the finished products neatly — reducing manual labor and improving production efficiency significantly.

We also prioritize after-sales support to ensure long-term reliable operation of the Z-type Light Steel Keel Roll Forming Machine. Our professional engineers provide remote quality assurance services, offering video online guidance whenever you encounter technical issues or need operational advice. This timely support minimizes downtime, saves maintenance costs, and ensures your production line runs smoothly.

Crafted with durable materials and advanced technology, the Z-type Light Steel Keel Roll Forming Machine boasts a long service life and low maintenance requirements. It is an ideal investment for construction material manufacturers, helping them improve production capacity, reduce costs, and meet the growing demand for high-quality light steel keels. Choose our Z-type Light Steel Keel Roll Forming Machine to elevate your production standards and gain a competitive edge in the market.

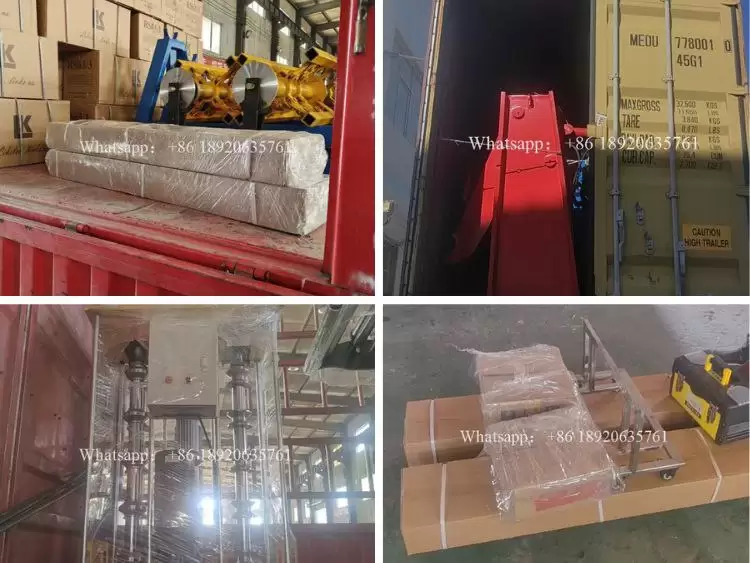

Our photos with our customers

About us

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the Z-type Light Steel Keel Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Z-type Light Steel Keel Roll Forming Machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.