Product

Z Type Light Keel Roll Forming Machine

Revolutionizing Construction with the Advanced Z Type Light Keel Roll Forming Machine

The construction industry is witnessing a significant transformation with the growing adoption of light steel framing systems. These modern building solutions offer exceptional strength, design flexibility, and sustainability compared to traditional construction methods. As a specialized manufacturer of cold roll forming equipment, we proudly present our state-of-the-art Z Type Light Keel Roll Forming Machine, a complete production solution engineered to manufacture high-precision Z-shaped light steel keels with remarkable efficiency and accuracy. This advanced system represents our commitment to delivering innovative manufacturing technology that meets the evolving demands of contemporary construction projects worldwide.

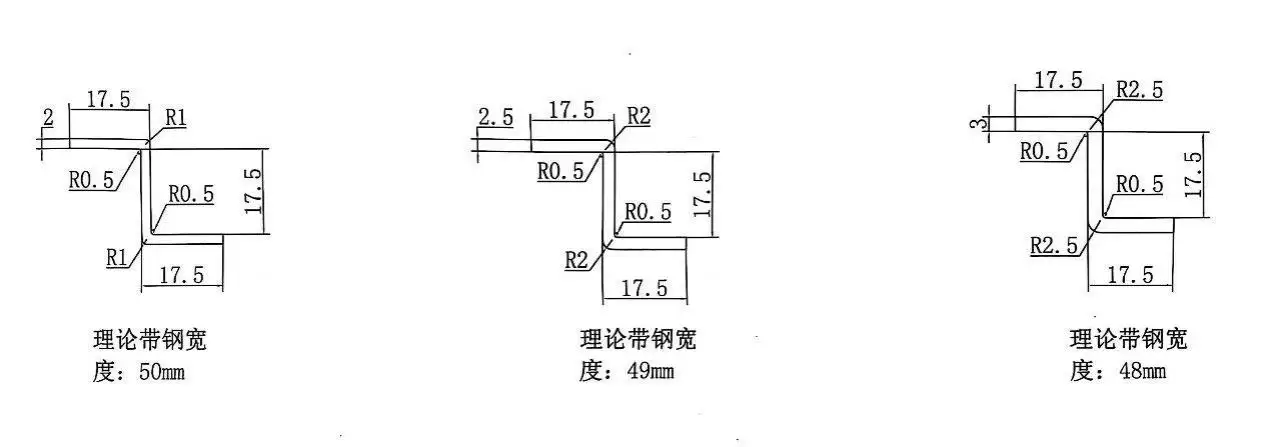

Diagram

More parameters

| Product Name | |

| Main motor power | 30KW Siemens main motor, K series gearbox |

| Hydraulic station | 7.5KW Siemens |

| Produce speed | 30 m/min |

| Shaft material | 45# Steel |

| Touch screen | PLC or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12 |

| Voltage | 415v 50hz 3p be customized |

| Feeding thickness |

1.5-3 mm

|

| Rows | 19th row |

| Shaft diameter | 80 mm |

| Cutting method | Hydraulic shutdown and cut-off |

| Cutting tolerance | +-1.0 mm |

| PLC display language | Chinese, English, Spanish (customizable) |

Our Z Type Light Keel Roll Forming Machine incorporates a fully automated production process that ensures consistent quality from raw material to finished product. The operation begins with an automatic decoiling system that feeds steel coils into the production line with precise tension control. The material then proceeds to the precision feeding mechanism, which maintains accurate positioning and steady advancement of the steel strip. The heart of the system is the advanced roll forming section, where computer-engineered rollers gradually shape the steel strip into the distinctive Z-profile configuration. This carefully calibrated process maintains uniform dimensions and structural integrity throughout production. Following the forming stage, a high-speed flying shear accurately cuts the continuous profile to required lengths, while the automated stacking system organizes the finished Z-profiles for convenient handling.

The Z Type Light Keel Roll Forming Machine stands out for its exceptional customization capabilities and user-friendly operation. Manufacturers can adjust critical parameters including material thickness, material width, operational voltage, and display language interface to meet specific project requirements. This flexibility ensures that the Z Type Light Keel Roll Forming Machine can be seamlessly integrated into diverse manufacturing environments, producing Z-profiles that comply with international quality standards. The machine's intelligent control system, featuring advanced PLC and touch-screen interfaces, allows operators to monitor and adjust production parameters with precision, ensuring consistent quality and optimal efficiency.

Beyond the advanced machinery, we provide comprehensive technical support to guarantee optimal performance. Our remote service program includes real-time video guidance from experienced engineers, who assist with machine installation, operational training, and troubleshooting through digital platforms. This support ensures that your Z Type Light Keel Roll Forming Machine maintains peak performance while minimizing potential downtime.

Investing in our Z Type Light Keel Roll Forming Machine represents a strategic decision to enhance manufacturing capabilities and market competitiveness. This sophisticated production solution enables manufacturers to produce high-quality Z-profiles with exceptional consistency, supporting the growing global demand for light steel framing systems in commercial, residential, and industrial construction projects.

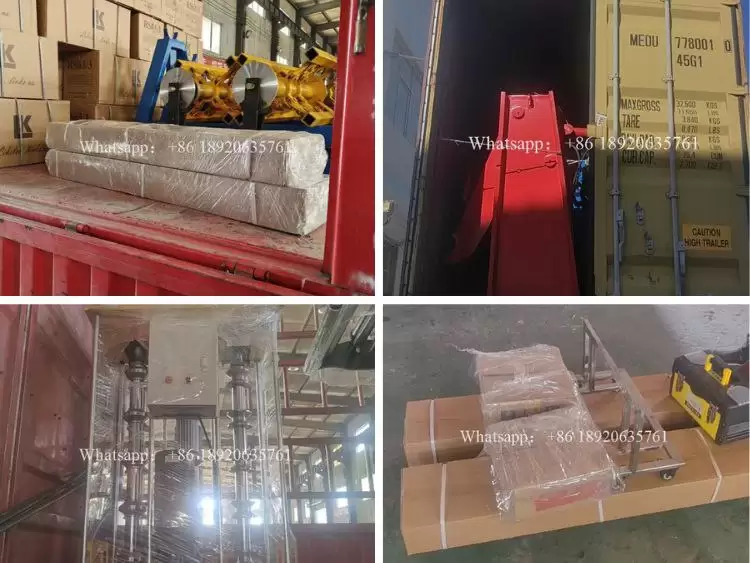

Our photos with our customers

About us

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the Z Type Light Keel Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Z Type Light Keel Roll Forming Machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.