Product

Achieve Unmatched Efficiency in Storage Solution Production with Our Upright Rack Roll Forming Machine Production Line

In the competitive world of industrial and commercial storage solutions, the ability to produce high-quality, custom upright racks efficiently is a significant advantage. Our company, a specialized manufacturer of cold roll forming machinery, introduces its state-of-the-art Upright Rack Roll Forming Machine Production Line. This fully integrated system is engineered to automate and streamline the entire manufacturing process, delivering exceptional precision, speed, and reliability for fabricating the critical vertical components of storage rack systems.

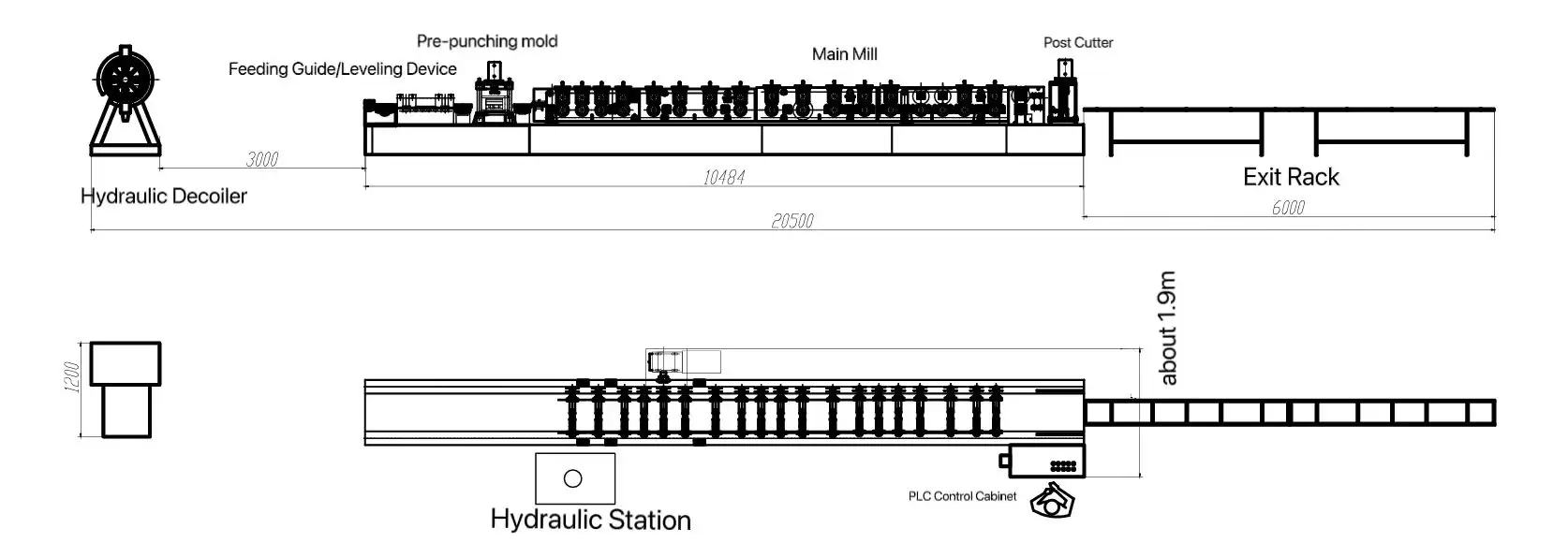

Workflow Diagram

Our Upright Rack Roll Forming Machine Production Line represents a complete, seamless workflow from raw material to finished product. The process begins with an automatic decoiler that feeds steel coil into the line. The material then proceeds through a precision punching station where holes are accurately created for subsequent assembly. This is followed by a flying shear that cuts the continuously formed profile to the exact required length. The heart of the system is the advanced roll forming machine, which gradually shapes the metal into the precise upright rack profile. The line culminates in an automatic stacking device, which neatly piles the finished uprights, ready for packaging or further processing.

A key strength of this Upright Rack Roll Forming Machine Production Line is its high degree of customization. We understand that every client has unique specifications. Therefore, critical parameters such as the size and position of the punching holes, as well as the material thickness accommodated by the roll forming mills, can be tailored to your exact needs. This flexibility ensures that the uprights produced meet the specific load-bearing and dimensional requirements of your customers.

More parameters

| Product Name | Upright Rack Roll Forming Machine Production Line |

| Punching | 80 ton mechanical punch press |

| Main motor power | 18.5 kw(Polaroid) |

| Hydraulic station | Vane pump, 5.5kw |

| Produce speed | 6-8 m/min |

| Shaft material | 45# Steel |

| Brand of electrical control cabinet |

Phase sequence protector Independent cabinet |

| Touch screen | Weilun or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12MOV, treatment off 58 ℃ -62℃ |

| Roller diameter | Φ80mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 1.5-2.5mm |

| Rows | 18 |

| Board height | 600-900 mm |

To facilitate a quick start-up, we commit to a swift 3-day drawing approval process. Our engineering team provides detailed layouts and technical drawings for your review, ensuring complete alignment with your expectations before production begins. Furthermore, we back our equipment with comprehensive remote support. Our engineers offer remote warranty services and real-time video guidance for installation, operational training, and troubleshooting, minimizing downtime and ensuring your Upright Rack Roll Forming Machine Production Line operates at peak performance from day one.

By integrating our Upright Rack Roll Forming Machine Production Line into your factory, you invest in unparalleled manufacturing efficiency, consistent product quality, and the agility to meet diverse market demands. It is the ultimate solution for producers aiming to lead in the storage equipment industry.

Application Scenario

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Upright Rack Roll Forming Machine Production Line for durable storage system. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Upright Rack Roll Forming Machine Production Line for durable storage system be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.