Product

High-quality Rack Upright Roll Forming Machine

Precision Engineered for Storage Solutions: The Rack Upright Roll Forming Machine

In the demanding world of warehousing and logistics, efficient storage solutions are paramount. At the heart of robust racking systems lie the critical upright columns, bearing the structural load. Manufacturing these vital components consistently, efficiently, and to exact specifications requires specialized equipment: the rack upright roll forming machine. This integrated production line represents a pinnacle of metal forming technology, designed specifically for the high-volume, precision fabrication of storage rack uprights.

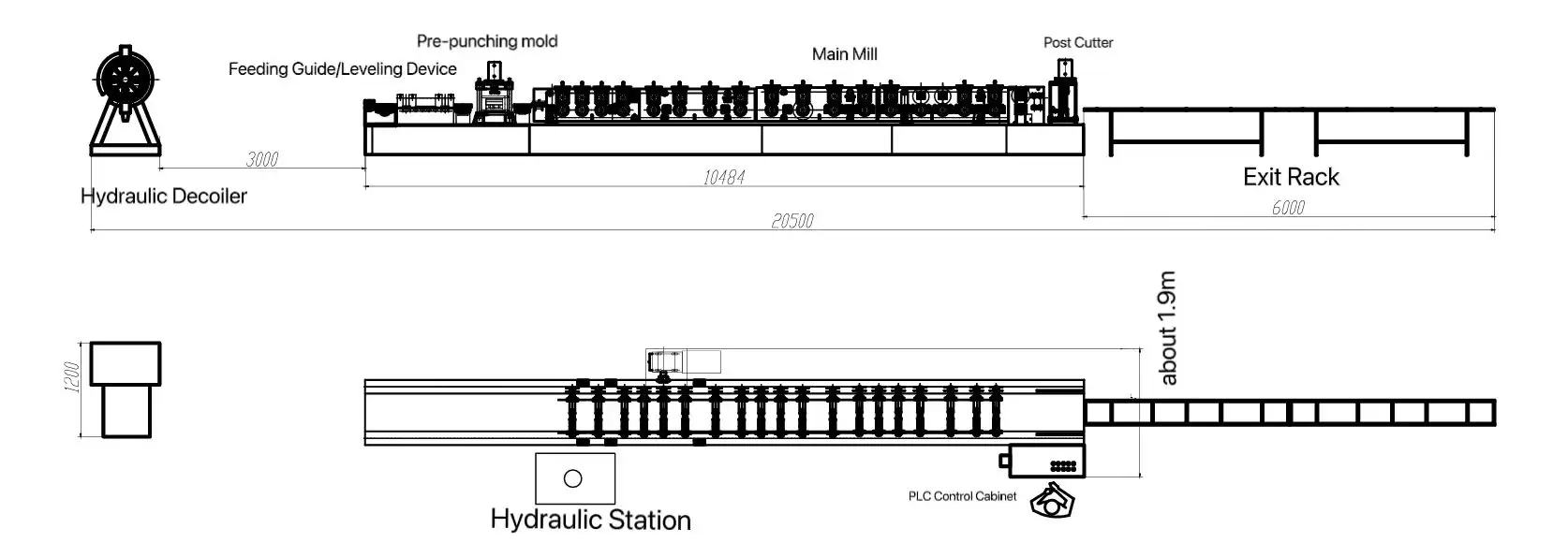

Workflow Diagram

More parameters

| Product Name | High-quality Rack Upright Roll Forming Machine |

| Punching | 80 ton mechanical punch press |

| Main motor power | 18.5 kw(Polaroid) |

| Hydraulic station | Vane pump, 5.5kw |

| Produce speed | 6-8 m/min |

| Shaft material | 45# Steel |

| Brand of electrical control cabinet |

Phase sequence protector Independent cabinet |

| Touch screen | Weilun or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Cr12MOV, treatment off 58 ℃ -62℃ |

| Roller diameter | Φ80mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 1.5-2.5mm |

| Rows | 18 |

| Board height | 600-900 mm |

Machine Introduction:

A rack upright roll forming machine is a fully integrated, automated production system. It transforms raw steel coil into finished rack upright profiles ready for assembly. Engineered for durability and high throughput, these machines handle various steel grades and thicknesses commonly used in the racking industry (typically light gauge steel). The core strength lies in its synchronized components working seamlessly: the uncoiler feeds the material, the precision leveler ensures perfect flatness, dedicated punching stations create the intricate hole patterns essential for shelf beam connections and adjustability, the multi-stage forming section gradually shapes the flat strip into the complex upright profile, and finally, a hydraulic cut system and stacker deliver finished, cut-to-length uprights.

Customization: Tailored to Your Needs

No two racking manufacturers have identical requirements. Modern rack upright roll forming machines are highly customizable. Key aspects include:

Material Handling: Adaptable for different coil weights, widths, and thicknesses.

Punching Flexibility: Configurable punching stations to accommodate diverse hole patterns, sizes, and spacing specific to your rack designs. CNC controls allow quick program changes.

Profile Versatility: Roll forming stations can be designed or modified to produce various upright cross-sections.

Length & Speed: Cutting systems and line speed can be tailored to desired production rates and standard upright lengths.

Automation Level: Options range from semi-automatic to fully automated lines with integrated material handling and packaging.

Application Scenario

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a High-quality Rack Upright Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the c be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.