Product

three waves highway guardrail roll forming machine

Engineering Safety at Scale: The Advanced Three Waves Highway Guardrail Roll Forming Machine

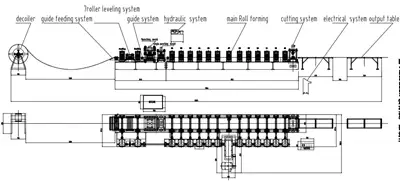

The Tree-Wave Highway Guardrail Roll Forming Machine integrates six precision processes into one automated production line, revolutionizing roadside safety infrastructure. This engineered system processes raw steel coils into standardized Tri-Wave guardrail profiles that meet specifications. The Tri-Wave Highway Guardrail Forming Machine can produce 15 meters of continuous guardrail per minute, with structural integrity that minimizes vehicle steering angles and ensures safety.

Workflow Diagram

More parameters

| Product Name | Three waves highway guardrail roll forming machine |

| Punching | Three groups, one group of middle holes and two groups of side holes |

| Structure | 500H Beam |

| Main motor power | Dual 22KW motors + K107 reducer |

| Hydraulic station motor power | 22kw |

| Cutting type | Hydraulic three-piece shear |

| Produce speed | 5-15m/min |

| Shaft material | Cr12MoV |

| Brand of electrical control cabinet | Delta or customized according to customer requirements |

| Touch screen/inverter | Delta or customized according to customer requirements |

| Rolling materials | High quality CR12 quenching |

| Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| Roller diameter | Φ120mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 2.0-4.0mm |

| Rows | 15-18 |

| Size | 14 meters long × about 2.4 meters wide |

| Voltage | 380V |

| Feeding width | 465- 475mm |

Integrated Production Workflow

Unwinding system

Dual motor hydraulic mandrel can handle 5-10 tons of coils (thickness 2.0-4.0 mm) and automatically center. The integrated design of the coil trolley ensures continuous operation during coil change. The powerful feeding system ensures uninterrupted material flow into the three waves highway guardrail roll forming machine.

Precision multi-roller leveling

The 15-stage leveling device with anti-scratch chrome rollers can eliminate coil bending and yield point elongation. Computer-controlled gap adjustment achieves a flatness tolerance of ±1.0 mm, which is essential to maintain the uniform waveform of the three waves highway guardrail roll forming machine.

Punching station

The punch press accurately punches the sheared sheet according to the predetermined value

Flying shear system

Hydraulic shears equipped with tungsten carbide blades cut the profiles at full line speed (5-15 meters per minute). Automatic length compensation adjusts for thermal expansion during the continuous operation of the Sanbo highway guardrail roll forming machine.

Progressive roll-forming process

The core component of the three-wave highway guardrail roll-forming machine is 15-18 forming frames, which perform three waves of forming simultaneously

Automatic stacking and handling to optimize transportation logistics.

Application Scenario

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a three waves highway guardrail roll forming machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the three waves highway guardrail roll forming machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.