Product

Precision steel slitting line

Precision Steel Slitting Line: Your Foundation for Flawless Metal Strip Production

In the demanding world of metal processing, achieving consistent, high-quality slit coils is paramount for countless downstream applications. Enter the precision steel slitting line – the engineered backbone of industries ranging from automotive and construction to appliances and electronics. More than just a cutting machine, a modern precision steel slitting line represents a sophisticated integration of mechanics, control systems, and material handling designed to transform wide master coils into multiple, perfectly dimensioned narrow strips with unparalleled accuracy and efficiency.

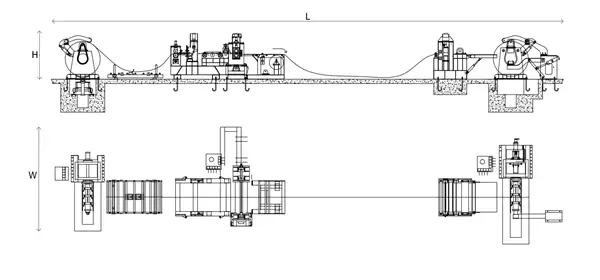

Roll Forming Process Workflow Diagram

More parameters

| Product Name | |

| Main motor power | 15 kw |

| Hydraulic station | 5.5 kw |

| Loading trolley | Height travel: 400mm; Length travel: 2.5m; Weight: 1.1t |

| Winder weight | 3.8 T |

| Feeding thickness | 0.3-0.8mm |

| Winder volume | 4*1.8*1.9 m |

| Feeding width |

0-1350mm |

| language |

Chinese, English, Spanish |

The operation of a precision strip slitting line follows a carefully designed sequence:

Uncoiling: The main coil is loaded onto a heavy-duty uncoiler (mandrel or expander). Hydraulic or pneumatic cylinders assist centering. Powered stripping arms ensure smooth front-end feeding. Tension winders or pneumatic brakes generate initial counter-tension.

Material entry and alignment: The strip passes through a threading table, which is usually equipped with a swing arm or an edge guidance system (EPC - Edge Position Control) to ensure that the material enters the critical slitting section in a perfectly aligned manner. This stage is crucial for the accuracy of the entire precision strip slitting line.

Precision slitting process: This is the heart of a precision strip slitting line. The strip is fed into the slitting head. Depending on the design (ring, pull-through or double ring), precise tension control is maintained. Rotating knives (upper and lower) or circular slitting knives perform the longitudinal cuts. A scrap shredder simultaneously cuts the offcuts into easily manageable pieces.

Leveling/flattening: After slitting, the strips pass directly through a precision multi-roller leveler. This critical component eliminates coil bends, bows, and edge waviness that were introduced during the previous coiling and handling process. The number, diameter, and adjustment of these leveling rollers determine the final flatness of the precision slitting line.

Separation and Guiding: Separation plates or pins gently separate the slit strips to prevent scratches and ensure clean feeding into the coiler. Side guides on each coiler precisely position the strip.

Precision Reeling: Independently powered coilers (usually twin-drum or center drive) wind each slit strip into a tight, properly tensioned coil. Taper tension control is often used to produce stable, non-telescopic coils. Line speed synchronization is critical here.

Unloading: After the mother coil is processed, the finished slit coil is usually unloaded by hydraulic arms or coil carts, ready for packaging or the next manufacturing process. The precision steel slitting line is then ready for the next mother coil.

The precision steel slitting line is far more than a simple cutting machine; it is a highly sophisticated, integrated production system fundamental to modern metal fabrication. By combining robust engineering, advanced control technology, and precision tooling, it delivers the consistent, high-tolerance slit material required by today's demanding industries. The ability to customize these lines ensures they meet exact production needs, while comprehensive after-sales support guarantees maximum uptime and longevity. Investing in a high-quality precision steel slitting line, backed by strong service, is an investment in the efficiency, quality, and competitiveness of your entire metal processing operation. It remains the cornerstone technology for transforming raw coil into the precise strips that build our world. The consistent output of a well-maintained precision steel slitting line directly impacts your bottom line through reduced scrap, higher yield, and faster downstream processing.

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the precision steel slitting line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the precision steel slitting line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.