Product

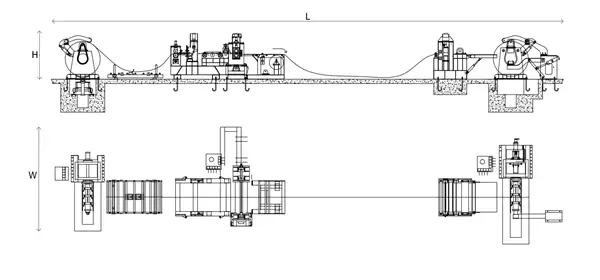

High-precision slitting machine for steel coil

The Slitting Machine for Steel Coil: Precision Engineered for Metal Transformation

In the bustling world of metal fabrication, where raw materials are transformed into the building blocks of countless industries, one machine stands as a cornerstone of efficiency and versatility: the Slitting Machine for Steel Coil. This sophisticated piece of industrial equipment is the engine behind converting massive, master steel coils into narrower, precisely dimensioned strips essential for everything from automotive components and appliances to construction profiles and electronic enclosures. Understanding its core functions – uncoiling, leveling, slitting, and recoiling – reveals the critical role this slitting machine for steel coil plays in modern manufacturing.

Roll Forming Process Workflow Diagram

More parameters

| Product Name | |

| Main motor power | 15 kw |

| Hydraulic station | 5.5 kw |

| Loading trolley | Height travel: 400mm; Length travel: 2.5m; Weight: 1.1t |

| Winder weight | 3.8 T |

| Feeding thickness | 0.3-0.8mm |

| Winder volume | 4*1.8*1.9 m |

| Feeding width |

0-1350mm |

| language |

Chinese, English, Spanish |

The Heart of the Process: Uncoiling and Feeding

The journey begins with the master coil, a heavy, tightly wound roll of steel. The slitting machine for steel coil starts by securely mounting this coil onto a robust uncoiler, often featuring motorized arms or hydraulic expandable mandrels. Precision is paramount here; consistent, controlled feeding into the subsequent stages is crucial. Many advanced slitting machine for steel coil systems incorporate sophisticated coil cars or hydraulic lifters to handle these substantial weights safely and efficiently. To ensure the strip enters the machine squarely, End Loop Control (ELC) systems or edge guiding sensors are frequently employed. This initial stage sets the foundation for the entire slitting machine for steel coil operation, demanding reliability and controlled material handling.

Achieving Flatness: The Critical Leveling Stage

Steel coil, having been wound under tension, inherently possesses internal stresses and slight curvature (crossbow, edge wave, coil set). Enter the precision leveler (or flattener). This vital component within the slitting machine for steel coil features a series of alternating upper and lower hardened steel rolls. As the steel strip passes through these rolls, they impart controlled bends, exceeding the material's yield point strategically. This plastic deformation effectively neutralizes internal stresses and eliminates imperfections, resulting in a perfectly flat strip. The effectiveness of the leveler directly impacts the quality of the final slit strips and their suitability for downstream processes like stamping or roll forming. The configuration and adjustment of the leveler are key strengths of a high-performance slitting machine for steel coil.

The Defining Operation: Precision Slitting

This is where the slitting machine for steel coil truly earns its name. The now-flat strip moves into the slitting head, the core of the slitting machine for steel coil. Here, pairs of extremely hard, circular shear knives (or slitter knives) are mounted on parallel arbors (shafts). The positioning of these knives determines the final width(s) of the slit strips. One arbor typically holds the stationary "male" knives, while the opposing arbor holds the "female" knives, which may be adjustable. The precise overlap and lateral clearance (side clearance) between these paired knives are critical parameters meticulously set for the specific steel grade, thickness, and desired edge quality. As the strip passes between these rotating knives, a shearing action occurs, cleanly separating it into multiple, narrower strips. Modern slitting machine for steel coil units offer quick knife change systems and highly accurate positioning mechanisms (manual, motorized, or CNC-controlled) to minimize setup time and maximize precision. Edge condition – whether cleanly sheared, slightly rolled, or micro-burred – is a key quality indicator determined by knife condition and setup.

Managing the Output: Separation and Recoiling

After slitting, the multiple narrow strips need to be effectively separated and neatly rewound.

The Recoiler: The final destination. Slit strips are wound onto individual collapsible steel mandrels. Dual mandrel systems allow continuous operation – one mandrel winds while the other is unloaded and prepared for the next set of coils. Powerful motors, often with sophisticated programmable tension profiles, ensure the new coils are wound to exacting standards of tightness and alignment. The recoiler design (single station, dual station, turret type) significantly impacts the overall productivity of the slitting machine for steel coil.

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the slitting machine for steel coil. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the slitting machine for steel coil be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.