Product

precision coil slitting machine line

The Backbone of Precision Metal Processing: Your Essential Coil Slitting Machine Line

In the dynamic world of metal fabrication and processing, efficiency, precision, and material yield are paramount. For industries ranging from construction and automotive to appliances and HVAC, transforming wide master coils of steel, aluminum, stainless steel, or other metals into precise, narrower strips is a fundamental requirement. This critical task falls to the workhorse of the secondary metal processing sector: the Coil Slitting Machine Line. More than just a single machine, a complete coil slitting machine line represents an integrated system meticulously engineered to handle the entire process – from raw coil preparation to finished, tightly wound slit coils ready for the next manufacturing stage.

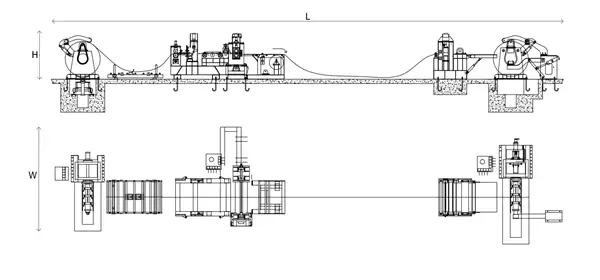

Roll Forming Process Workflow Diagram

More parameters

| Product Name | |

| Main motor power | 15 kw |

| Hydraulic station | 5.5 kw |

| Loading trolley | Height travel: 400mm; Length travel: 2.5m; Weight: 1.1t |

| Winder weight | 3.8 T |

| Feeding thickness | 0.3-0.8mm |

| Winder volume | 4*1.8*1.9 m |

| Feeding width |

0-1350mm |

| language |

Chinese, English, Spanish |

Understanding the Core Function: What is a Coil Slitting Machine Line?

Simply put, a coil slitting machine line is a continuous processing system designed to unwind (decoil) a large master coil of metal, precisely slit it longitudinally into multiple narrower strips of predetermined widths, and then rewind (recoil) these strips onto individual smaller mandrels. The term "line" is crucial, signifying the seamless integration of several key components working in concert. The primary goal is high-volume production of slit coils with consistent width, excellent edge quality, minimal material waste, and optimal flatness, all achieved with maximum operational efficiency. Investing in a robust coil slitting machine line is an investment in productivity and product quality for any metal service center or fabricator.

Deconstructing the Process: Key Components of a Coil Slitting Machine Line

Uncoiling/Decoiling: The process begins here. A heavy-duty uncoiler securely holds the master coil. Using either expanding mandrels or hydraulic arms, it feeds the leading end of the coil into the line. Critical features include adjustable tension control (often via a pneumatic or hydraulic brake) to prevent material buckling or stretching, and optional coil cars or lifters for efficient loading. The stability and control provided by the uncoiler set the foundation for the entire coil slitting machine line.

Straightening/Leveling: Metal coils inherently possess curvature (coil set) and may exhibit crossbow or edge wave. Passing through a precision multi-roll leveler is essential. These straightening rolls, arranged in staggered configurations, apply carefully calibrated bending stresses to the metal, effectively eliminating these imperfections and delivering perfectly flat material to the slitting head. Consistent flatness is non-negotiable for achieving precise slit widths and preventing edge damage further down the coil slitting machine line.

The Slitting Head: Heart of Precision: This is where the actual width division happens. The slitting head houses the critical tooling:

Circular Knives (Slitter Blades): Hardened steel or carbide-tipped circular blades mounted on arbors. These come in various profiles (planar, bevelled, razor) suited to different materials and thicknesses.

Spacers (Distance Collars/Washers): Precision-ground collars placed between the blades on the arbors determine the exact slit width. Micrometer adjustments allow for extremely fine width tolerances.

Drives: The arbors holding the blades and spacers are driven, rotating the blades at the correct surface speed matching the line speed. Precision bearings and robust drives are essential for vibration-free operation and consistent edge quality throughout the coil slitting machine line run.

Scrap Winders (Optional but Common): Especially important when slitting multiple narrow widths, edge trim scrap is generated. Integrated scrap winders efficiently coil this trim material for recycling, maintaining a clean work area and maximizing overall yield of the coil slitting machine line.

Guiding & Edge Trimming (Pre-Slit): Before reaching the slitting head, edge guides ensure the master coil is perfectly aligned. Rotary side trimmers can clean up uneven or damaged master coil edges, ensuring only high-quality material enters the slitting process and optimizing the performance of the coil slitting machine line.

Separator Fingers: Immediately after the slitting head, thin, rigid fingers (often made of hardened steel or nylon) drop down between the newly slit strips. This prevents strips from overlapping or scratching each other as they travel towards the recoilers – a vital step in maintaining strip integrity within the coil slitting machine line.

Recoiling/Tension Control: Individual slit strips are fed onto their respective recoiler mandrels. This stage demands sophisticated tension control, typically achieved through precision drive motors, load cells, and dancer rolls. Maintaining consistent tension throughout the recoiling process is critical for achieving tight, stable, and telescoping-free slit coils. Modern coil slitting machine line recoilers often feature automatic mandrel expansion/contraction and programmable coil doffing (removal) sequences. Dual recoilers allow for continuous operation – one recoiler winds while the other is unloaded.

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the coil slitting machine line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the coil slitting machine line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.