Product

High-precision Cable Tray Bending Machine

High-precision Cable Tray Bending Machine: The Ultimate Solution for Custom Cable Support Manufacturing

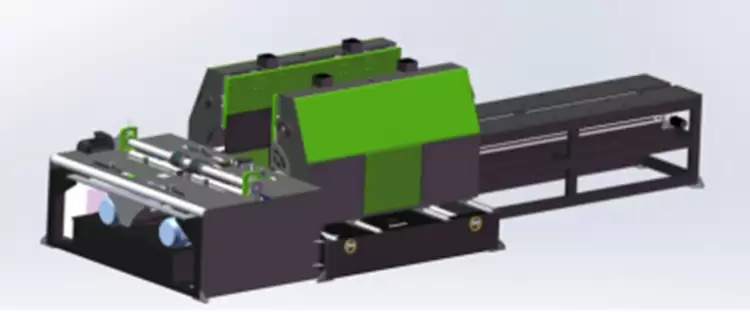

In the demanding field of electrical infrastructure, the quality of cable support systems is non-negotiable. Our High-precision Cable Tray Bending Machine is specifically engineered to meet this critical demand for accuracy and reliability. This state-of-the-art equipment serves as the cornerstone for manufacturers who refuse to compromise on quality, transforming pre-sheared and pre-punched metal plates into perfectly formed cable trays with exceptional consistency.

Workflow Diagram

The core function of our CNC Cable Tray Bending Machine is to automate the critical bending process. Operators simply load the flat metal profile, and the machine takes over, executing complex bends according to digitally programmed parameters. This guarantees that every bend, angle, and dimension is produced with extreme accuracy, batch after batch. The versatility of this CNC Cable Tray Bending Machine is a key advantage. Whether you require standard shapes like ladder-type or trough-style trays, or something entirely custom, our machine can be programmed to accommodate. The bending width, angles, and overall form are fully customizable to meet specific project blueprints and load-bearing requirements.

The primary operation of our High-precision Cable Tray Bending Machine is a marvel of modern engineering. The process begins with a flat metal sheet that has already been cut to size and perforated. This blank is then loaded into the machine, where a computer numerically controlled (CNC) system takes command. It executes a series of complex bends with impeccable accuracy, strictly following pre-programmed parameters that dictate every angle, radius, and dimension. This eliminates human error and ensures that every single tray produced is identical to the last, guaranteeing structural integrity and a perfect fit during installation.

A defining feature of this High-precision Cable Tray Bending Machine is its remarkable flexibility. The machine is not limited to standard designs. Whether your project requires standard ladder-type trays, robust trough-style trays, or a completely unique profile to fit a specific architectural constraint, our machine can be programmed to deliver. The bending width, angles, and overall geometry are fully customizable, allowing you to respond agilely to custom project specifications and diverse load-bearing requirements.

To support rapid prototyping and fast-paced production schedules, we promise a swift design turnaround. Our engineering team can provide detailed and production-ready drawings within just three days of receiving your specifications. This efficiency ensures your manufacturing process remains on track and ahead of deadline.

Our partnership with clients extends well beyond the sale. We provide comprehensive remote warranty support and real-time video guidance. Our seasoned engineers can connect online to perform diagnostics, offer operational assistance, and provide training, ensuring your High-precision Cable Tray Bending Machine operates at maximum efficiency with minimal downtime. Investing in this machine means investing in a partnership dedicated to your productivity and success, making it the smart choice for advanced cable tray manufacturing.

More parameters

| Product Name | High-precision Cable Tray Bending Machine |

| CNC bending part | Automatic feed port identification Servo opening and closing Precision-ground forming tools Opening and closing motor power (5.5kW) |

| Discharging station | 4-meter servo-assisted discharge Main motor power (1.5 kW) Anti-collision material limiter |

| Hydraulic station | Multiple solenoid valves Solenoid overflow valve Cooling system Motor power (7.5 x 2) kW Oil tank capacity (400 liters) |

| Produce speed |

4-6 m/min |

| Rolled strip material | Q235 cold rolled sheet, galvanized sheet |

| Voltage | 380V,50Hz,3p be customized |

| Feeding thickness | 1.5(±0.03)—2.0(±0.03) mm |

| Equipment footprint | 6.5×2.5×2M |

| Feeding width | 200-1250 mm |

| Molding specifications | 800/200-100/50 (single and double folding) |

Application Scenario

Our Certificate

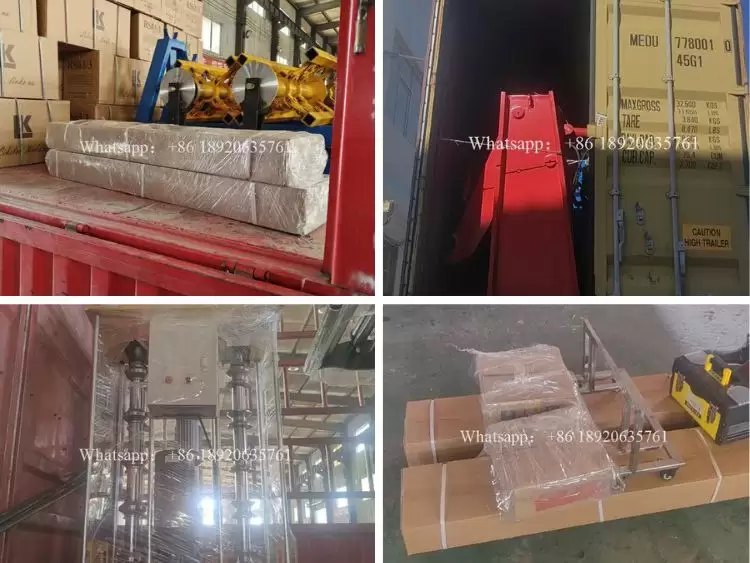

Transportation and delivery