Product

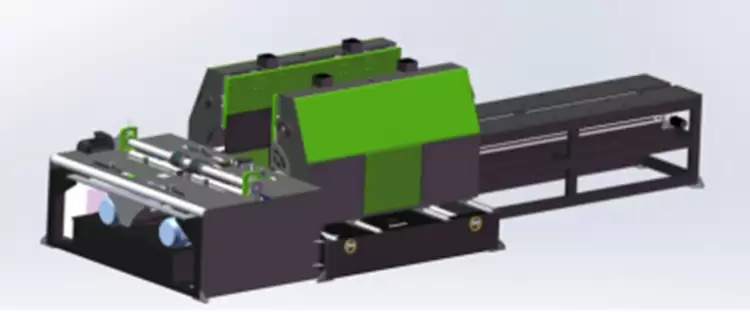

Cable Tray Bending Machine

Innovate Your Production with Advanced Cable Tray Bending Machine

As a professional manufacturer of roll forming equipment, we take pride in introducing our state-of-the-art Cable Tray Bending Machine, designed to revolutionize your cable tray manufacturing process. This advanced Cable Tray Bending Machine offers unparalleled precision and efficiency in producing high-quality cable trays for various industrial applications. Our machine represents the perfect combination of innovative technology and robust engineering, ensuring reliable performance and exceptional results.

Workflow Diagram

The Cable Tray Bending Machine features a comprehensive bending system that allows for complete customization of bending shapes and widths. Whether you need standard designs or specialized configurations, our Cable Tray Bending Machine can accommodate your specific requirements with remarkable accuracy. The machine's sophisticated control system ensures consistent bending quality and repeatability, making it an ideal solution for both mass production and custom orders. With our Cable Tray Bending Machine, manufacturers can achieve perfect bends every time, eliminating product defects and material waste.

One of the key advantages of our Cable Tray Bending Machine is its user-friendly operation and maintenance. The intuitive interface allows operators to easily program and adjust bending parameters, while the robust construction ensures long-term durability and minimal downtime. Our technical team provides comprehensive support, including detailed engineering drawings within three days and remote video guidance for operation and maintenance. This commitment to customer service ensures that our clients can maximize the potential of their Cable Tray Bending Machine investment.

The versatility of our Cable Tray Bending Machine makes it suitable for various material types and thicknesses, providing manufacturers with the flexibility to meet diverse project requirements. The machine's precision engineering guarantees accurate bending angles and dimensions, ensuring that every cable tray meets the highest quality standards. By choosing our Cable Tray Bending Machine, manufacturers can significantly enhance their production capabilities, reduce labor costs, and improve overall efficiency.

Our company stands behind the quality and performance of the Cable Tray Bending Machine with comprehensive remote technical support and warranty services. Engineers are available for video consultations and online guidance, ensuring smooth operation and quick troubleshooting. This dedicated support system, combined with the machine's advanced features, makes our Cable Tray Bending Machine an invaluable asset for any cable tray manufacturing operation looking to stay competitive in today's market.

Investing in our Cable Tray Bending Machine means investing in quality, efficiency, and innovation. Contact us today to learn how our Cable Tray Bending Machine can transform your manufacturing process and help you achieve new levels of productivity and success.

More parameters

| Product Name | Cable Tray Bending Machine |

| CNC bending part | Automatic feed port identification Servo opening and closing Precision-ground forming tools Opening and closing motor power (5.5kW) |

| Discharging station | 4-meter servo-assisted discharge Main motor power (1.5 kW) Anti-collision material limiter |

| Hydraulic station | Multiple solenoid valves Solenoid overflow valve Cooling system Motor power (7.5 x 2) kW Oil tank capacity (400 liters) |

| Produce speed |

4-6 m/min |

| Rolled strip material | Q235 cold rolled sheet, galvanized sheet |

| Voltage | 380V,50Hz,3p be customized |

| Feeding thickness | 1.5(±0.03)—2.0(±0.03) mm |

| Equipment footprint | 6.5×2.5×2M |

| Feeding width | 200-1250 mm |

| Molding specifications | 800/200-100/50 (single and double folding) |

Application Scenario

Our Certificate

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a cable tray bending machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the cable tray bending machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.