Product

EPS Panel Sandwich Machine Production Line

Automating Building Innovation with the Customizable EPS Panel Sandwich Machine Production Line

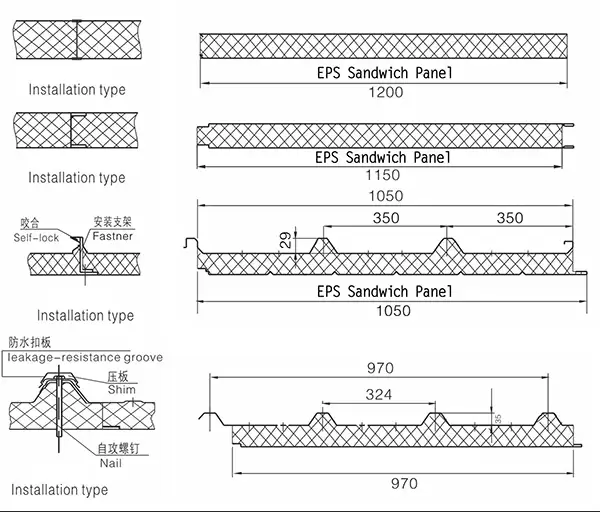

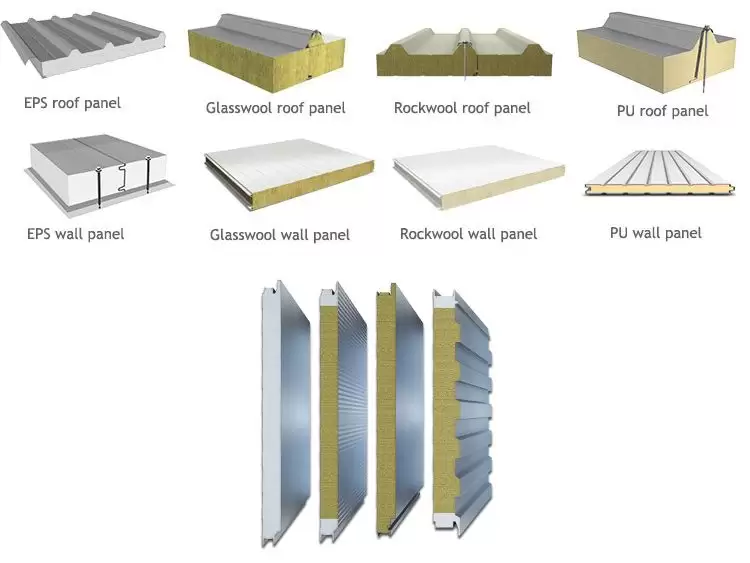

The global construction sector is prioritizing solutions that deliver speed, sustainability, and superior energy performance. At the forefront of this shift are insulated sandwich panels, with EPS (Expanded Polystyrene) core panels being a benchmark for efficiency and versatility. To meet the exacting standards of modern manufacturing, we present our fully automated EPS Panel Sandwich Machine Production Line. This integrated system is engineered to transform raw materials into high-performance wall and roof panels with precision and consistency. The EPS Panel Sandwich Machine Production Line represents more than machinery; it is a complete, customizable production ecosystem designed for manufacturers seeking to excel in the prefabricated building component market.

More parameters

| Product Name | EPS Panel Sandwich Machine Production Line |

| Total power of equipment | 40 kw |

| Operating voltage | 380 V(Customizable) |

| Produce speed | 0-6 m/min |

| Electrical control system | The PLC is operated by Delta, featuring a 7-inch color touchscreen; the frequency converter is Delta; the counter is Omron; the motor is Shanghai Lichao; and the glue pump is Shanghai Shuangzhou. |

| Color steel sheet thickness | 0.2-0.6mm |

| Roll forming machine part | Forming row: 16 rows; Shaft diameter: ф70 mm; Motor: 5.5kw |

| Product thickness |

EPS: 50-250mm Rock wool: 50-100mm |

| Composite host section | 52-pass roll forming process (roller diameter 180mm) |

| Feeding width | 1000mm/1200mm |

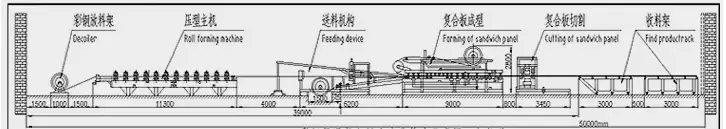

| Production line size | Composite main unit length: 9 meters; Feeding mechanism: 6.5 meters; Cutting machine: 4 meters (recessed front cutting); Feeding section: 6-meter conveyor belt; Total equipment length: 38 meters; Total equipment width: 2.2 meters; Total equipment height: 2.4 meters |

| Equipment operating area | 45m*7m*4 m |

| Material and thickness | a. EPS foam thickness: 30-250mm b. Rock wool: 50-100mm |

| Glue pump dispensing volume | 0~0.4 kg per dose |

| Glue (black glue: white glue) | 1:1 |

| Glue application speed | 80 times/minute |

| Cutting system |

Weight:~ 1.0 t Drive motor:1.5kw×2 Sandwich Panel length: >= 1500mm |

Production Process

Precision engineering defines every stage of the EPS Panel Sandwich Machine Production Line. The automated process begins with decoiling, feeding pre-finished steel coils into the line. The material is first notched and then formed into a rigid, structural profile through corrugation rolling. The core bonding sequence follows, featuring a precise adhesive application system that performs drip gluing and even spreading. The EPS core is then laminated to the metal skin under controlled conditions, creating a permanent, high-strength bond. Finally, the continuous panel is cut to a preset length and transferred via a conveyor rack for final handling. This seamless integration within the EPS Panel Sandwich Machine Production Line guarantees panels with exceptional flatness, consistent insulation value, and reliable structural integrity batch after batch.

The application scope for panels produced on this EPS Panel Sandwich Machine Production Line is vast, covering critical needs in industrial, commercial, and cold chain logistics. They are the preferred material for constructing energy-efficient exterior walls and durable, insulated roofing systems for factories, warehouses, agricultural buildings, and retail spaces. Their exceptional thermal performance makes them indispensable for cold storage facilities, food processing plants, and climate-controlled environments. Understanding that project requirements vary, our EPS Panel Sandwich Machine Production Line is highly customizable, allowing adjustments in panel width, thickness, profile design, and production speed to meet specific market demands and client specifications.

To ensure your investment operates at peak efficiency, we provide comprehensive remote support. Our engineers offer real-time video guidance for installation, operational training, troubleshooting, and preventative maintenance, minimizing downtime and protecting the productivity of your EPS Panel Sandwich Machine Production Line.

Investing in this advanced EPS Panel Sandwich Machine Production Line is a strategic move to capture a significant share of the growing insulated panel market. It empowers your business to supply high-value, custom-engineered building solutions that reduce construction time and lifetime energy costs for end-users. By deploying this sophisticated and adaptable EPS Panel Sandwich Machine Production Line, you are not merely purchasing equipment—you are activating a turnkey production capability for the future of construction.

Application scenarios

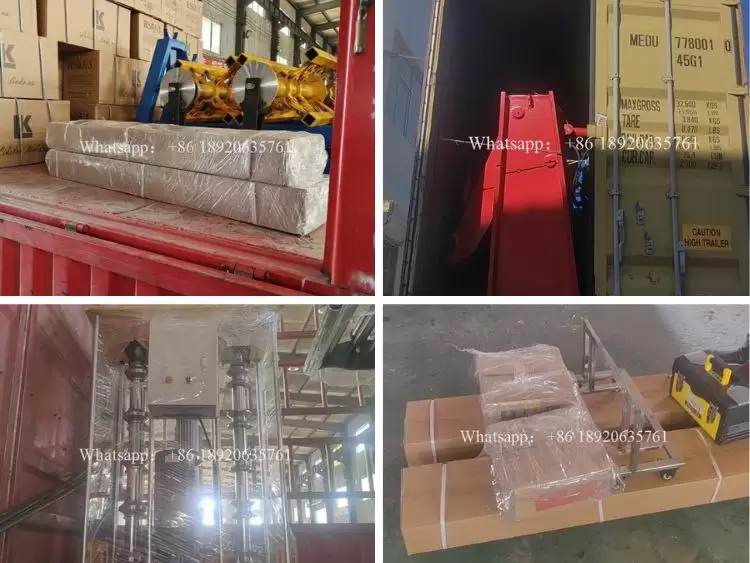

Our photos with our customers

Our Certificate

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a EPS Panel Sandwich Machine Production Line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the EPS Panel Sandwich Machine Production Line be completed in 30 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.