Product

The Engine of Efficient Shelving: Your Shelf Box Panel Making Machine

In the fast-paced world of logistics, warehousing, and retail, robust and readily available shelving is fundamental. The core component of countless storage systems is the shelf deck itself – often designed as a strong, cost-effective box profile panel. Manufacturing these panels efficiently, consistently, and to high standards demands specialized automation: the integrated Shelf Box Panel Making Machine. This advanced production line is engineered specifically for the high-volume, precision fabrication of shelf box panels, forming the backbone of reliable storage solutions.

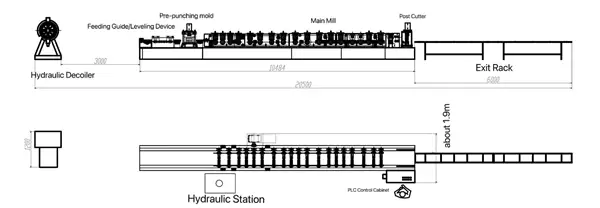

Workflow Diagram

More parameters

| Product Name | High-performance shelf box panel making machine |

| Main motor power | 15 kw(Siemens) |

| Hydraulic station | Vane pump, 7.5 kw |

| Produce speed | 20 m/min |

| Shaft material | 45# Steel |

| Brand of electrical control cabinet |

Phase sequence protector Independent cabinet |

| Touch screen | Siemens or customized according to customer requirements |

| Rolling materials | Cr12, heat treatment HRC58-62℃ |

| Cutting blade material | Hydraulic back shear (three blades) cutter material Cr12MoV |

| Roller diameter | Φ75 mm |

| Voltage | 380v 60hz 3p be customized |

| Feeding thickness | 1.5-2.0 mm |

| Rows | 14 |

| Board height | 600-900 mm |

Machine Introduction:

A Shelf Box Panel Making Machine is a fully automated, continuous production system designed to transform raw steel coil into finished, box-section shelf panels ready for assembly. Built for durability and maximum throughput, it handles the light-gauge steel (typically 1.5mm to 2.0mm) commonly used for shelving decks. The machine's power lies in its seamlessly synchronized components: the uncoiler feeds the coil, precision leveling ensures perfectly flat material essential for quality forming, the multi-stage roll forming section meticulously shapes the flat strip into the rigid box profile, and a high-speed cutting and stacking system delivers finished, cut-to-length panels. This integrated approach guarantees dimensional accuracy and structural integrity.

Dedicated Support: Partnering in Your Success

Investing in a Shelf Box Panel Making Machine is a strategic decision for your manufacturing capacity. Leading suppliers provide comprehensive after-sales service to ensure peak performance and longevity:

Expert Installation & Commissioning: Skilled technicians ensure precise setup, calibration, and optimization for your specific materials and products.

Thorough Training: Comprehensive operator training focuses on safe, efficient operation and basic troubleshooting. Maintenance training ensures your team can perform essential upkeep.

Responsive Technical Support: Access to experienced engineers via phone, email, or remote diagnostics for rapid troubleshooting and process optimization guidance.

Genuine Spare Parts: Guaranteed availability of original equipment manufacturer (OEM) parts to minimize costly downtime.

Application Scenario

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a High-performance shelf box panel making machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the High-performance shelf box panel making machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.