Product

Color Stone Coated Roof Production Line

Color Stone Coated Roof Production Line

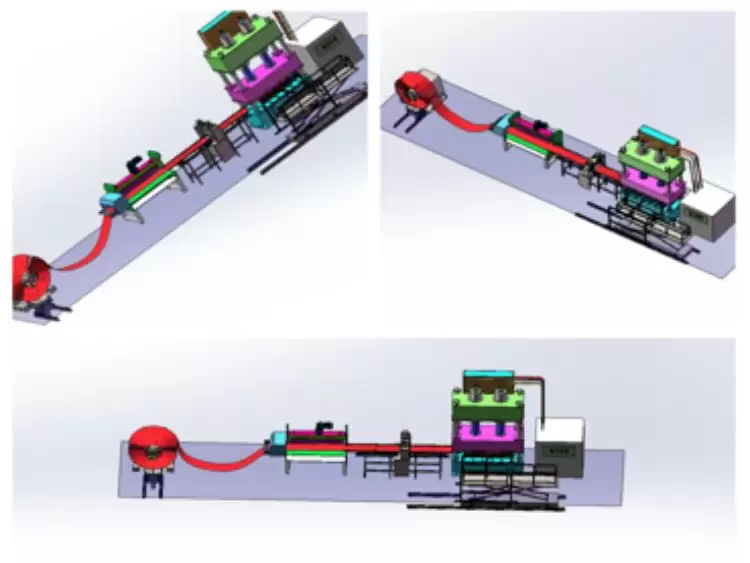

In the realm of modern construction materials, stone-coated metal roofing stands as a superior choice, combining the durability of steel with the timeless aesthetic of natural stone or ceramic. Manufacturing this premium product demands precision, consistency, and a deep understanding of composite material technology. Our Color Stone Coated Roof Production Line embodies this expertise, offering a fully integrated, automated, and customizable solution designed to transform high-strength steel coils into beautiful, high-performance roofing sheets.

Precision Engineering: A Step-by-Step Manufacturing Process

Our Color Stone Coated Roof Production Line orchestrates a seamless, multi-stage process to guarantee product integrity:

Material Preparation: The process begins with high-strength Galvalume steel coil as the robust substrate. Concurrently, natural sintered color granules and specialized acrylic resin adhesive are prepared for coating.

Cutting and Profiling: The steel coil is uncoiled, leveled, and precisely cut. It then passes through a precision roll-forming machine, where it is cold-formed into various designed profiles, such as classic tile waves or shake patterns.

Adhesive Application: The profiled metal sheet is uniformly coated with a key layer of acrylic resin adhesive, which acts as the critical bonding agent between the metal substrate and the stone granules.

Granule Distribution & Cleaning: Sintered color granules are evenly distributed across the adhesive-coated surface, creating the authentic stone-like texture and color. An air-knife system then removes any loose granules, ensuring optimal and even coverage.

High-Temperature Curing: The coated sheet enters a controlled curing oven. Here, a two-stage high-temperature curing process permanently bonds the granules and primer to the metal, resulting in exceptional adhesion, weatherproofing, and color fastness that defines the final product's longevity.

| Glue Spraying Chamber | Color Stone Coated Roof Production Line |

| Dimensions | 4200 × 1800 × 2200 mm (Length × Width × Height) |

| Main Frame | 120# channel steel |

| Spraying Method | Fixed high-pressure spray gun for coating |

| Transmission Method | Driven by a 0.75kW motor, with round belt transmission |

| Control System | PLC control with LCD display for parameter adjustment |

| Spraying Device | Electric hydraulic spray machine |

Key Advantages and Distinctive Features

Investing in our Color Stone Coated Roof Production Line provides a formidable competitive edge through several core benefits:

Uncompromising Product Quality: The line ensures uniform granule distribution, vibrant color consistency, and a flawless finish that replicates natural materials while offering superior durability, fire resistance, and hail impact resistance.

High Efficiency & Automation: From coil feeding to final stacking, the fully automated Color Stone Coated Roof Production Line maximizes production output, minimizes labor costs, and ensures consistent, high-speed operation with minimal material waste.

Complete Customization Flexibility: Every aspect of the Color Stone Coated Roof Production Line can be tailored. This includes the sheet profile design, coating colors and granule blends, production speed, and overall line configuration, allowing manufacturers to cater to diverse architectural styles and market demands.

Robust Technical Support: We provide end-to-end partnership, including comprehensive remote support and real-time video engineering guidance for troubleshooting and maintenance, ensuring your Color Stone Coated Roof Production Line maintains optimal productivity and uptime.

| Sanding and Blasting Section | Color Stone Coated Roof Production Line |

| Dimensions | 8500 × 1800 × 2500 mm (Length × Width × Height) |

| Main Frame | 120# channel steel |

| Transmission Method | 6mm chain for cyclic transmission |

| Motor Power | 2.2kW (shared with the glue spraying chamber) |

| Sand Supply Method | Independent sand box for replenishment, with excess colored sand recycled using three belt conveyors in a reciprocating cycle. |

| Surface Glue Spraying Section | Color Stone Coated Roof Production Line |

| Dimensions | 5600 × 1800 × 2200 mm (Length × Width × Height) |

| Main Frame | 120# channel steel |

| Spraying Method | Reciprocating spraying |

| Transmission Method | 0.75kW motor, round belt transmission |

| Control System | PLC control, with LCD display for parameter adjustment |

| Spraying Device | Uses a diaphragm pump for surface glue adsorption, with a high-pressure spray gun for reciprocating spraying. |

| Drying Main Body | Color Stone Coated Roof Production Line |

| Dimensions | 60000 × 1750 × 1700 mm (Length × Width × Height) |

| Main Frame | Welded using national standard 180# channel steel and 50mm steel pipes. The bottom is insulated with 50mm thick rock wool composite boards. |

| Transmission Method | 5kW frequency-controlled motor, 1.2-inch national standard chain for cyclic transmission. The tile brackets are made by bending Φ10mm cold-drawn rods |

| Heating Method | Electric heating air furnace, 100kW (2 units) |

| Insulation Boards | Insulation includes top and side insulation. Side insulation consists of 100mm thick polyurethane-sealed rock wool composite boards, while the top insulation is also 100mm thick polyurethane-sealed rock wool composite boards. |

| Extended Tile Drying Chamber | Color Stone Coated Roof Production Line |

| Drying Main Body Dimensions | 60000 × 1750 × 1700 mm (Length × Width × Height) |

| Main Frame | Welded using national standard 180# channel steel and 50mm steel pipes. The bottom is insulated with 50mm thick rock wool composite boards for thermal protection |

| Transmission Method | 5kW frequency-controlled motor, 1.2-inch national standard chain for cyclic transmission. The tile brackets are made by bending Φ10mm cold-drawn rods |

| Heating Method | Electric heating air furnace, 100kW (2 units) |

| Insulation Boards | Insulation includes top and side insulation. Side insulation consists of 100 mm-thick polyurethane-sealed rock wool composite boards, and the top insulation is also 100 mm-thick polyurethane-sealed rock wool composite boards |

Application and Market Potential

This advanced production line is engineered for manufacturers serving the residential, commercial, and architectural roofing sectors. The final product is ideal for projects requiring a perfect blend of aesthetic elegance, long-term durability, and proven performance in harsh climates.

By integrating precision roll-forming with advanced coating and curing technology, our Color Stone Coated Roof Production Line is more than just machinery—it is a strategic gateway to producing premium roofing materials that command market leadership and deliver exceptional customer value.

Application Scenario

This production line is designed for manufacturers targeting the premium residential, commercial, and architectural roofing markets. The final product is ideal for new construction and renovation projects requiring a combination of longevity, aesthetic beauty, and performance.

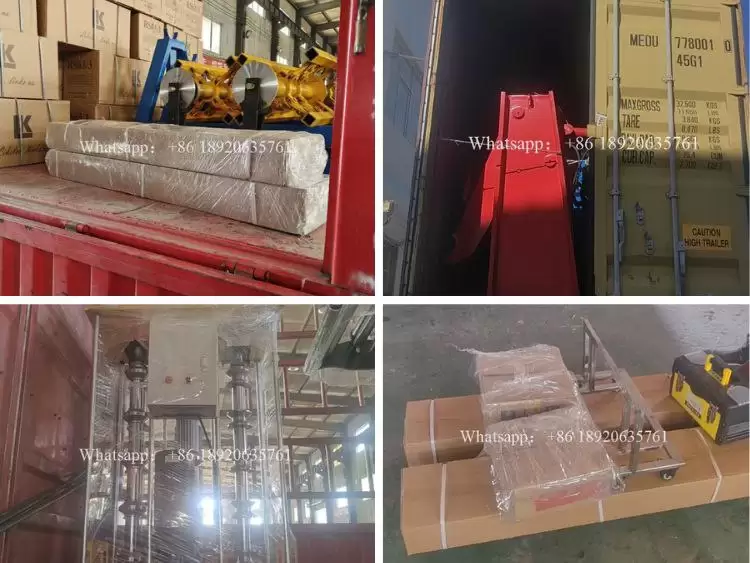

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Color Stone Coated Roof Production Line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Color Stone Coated Roof Production Line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.