Producto

Two-wave Guardrail Roll Forming Machine Manufacturers

Leading Innovation as Premier Two-wave Guardrail Roll Forming Machine Manufacturers

As specialized Two-wave Guardrail Roll Forming Machine Manufacturers, we understand the critical role that highway safety systems play in modern infrastructure development. The consistent quality and precision of guardrail systems directly impact road safety outcomes, which is why our engineering team has developed an advanced production solution that sets new standards in the industry. Our expertise as experienced Two-wave Guardrail Roll Forming Machine Manufacturers enables us to deliver equipment that produces guardrails meeting stringent international safety specifications while optimizing production efficiency for our clients worldwide.

Workflow Diagram

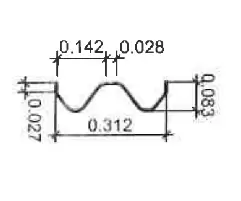

The production process integrated into our system as professional Two-wave Guardrail Roll Forming Machine Manufacturers follows a meticulously engineered workflow. It begins with automatic decoiling that ensures smooth material feeding into the production line. The steel strip then progresses through precision punching stations where mounting holes are created with absolute accuracy. Following this, our advanced flying shear system cuts the continuously formed profile to exact lengths without stopping the production flow. The core of our manufacturing excellence as Two-wave Guardrail Roll Forming Machine Manufacturers is demonstrated in the roll forming section, where the distinctive two-wave profile is gradually shaped through a series of precision-engineered rollers, ensuring consistent dimensional accuracy throughout production.

More parameters

| Product Name | Two-wave Guardrail Roll Forming Machine Manufacturers |

| Punching | Three groups, one group of middle holes and two groups of side holes |

| Structure | 500H Beam |

| Main motor power | Dual 22KW motors + K107 reducer |

| Hydraulic station motor power | 22kw |

| Cutting type | Hydraulic three-piece shear |

| Produce speed | 5-15m/min |

| Shaft material | Cr12MoV |

| Brand of electrical control cabinet | Delta or customized according to customer requirements |

| Touch screen/inverter | Delta or customized according to customer requirements |

| Rolling materials | High quality CR12 quenching |

| Cutting blade material | Cr12, treatment off 58 ℃ -60 ℃ |

| Roller diameter | Φ120mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 2.0-4.0mm |

| Rows | 15-18 |

| Size | 14 meters long × about 2.4 meters wide |

| Voltage | 380V |

| Feeding width | 465- 475mm |

What sets us apart as leading Two-wave Guardrail Roll Forming Machine Manufacturers is our commitment to customization and technical support. We recognize that different projects may require specific adaptations, which is why our equipment allows for adjustments in punching patterns, material thickness, and profile dimensions. Our pledge as responsive Two-wave Guardrail Roll Forming Machine Manufacturers includes providing comprehensive technical drawings within three days of order confirmation, ensuring rapid project initialization. This expedited documentation process reflects our understanding of tight project timelines in the infrastructure sector.

Beyond equipment delivery, our service as dedicated Two-wave Guardrail Roll Forming Machine Manufacturers extends to comprehensive after-sales support. We provide remote warranty services through real-time video guidance, enabling our engineers to assist with installation, operational training, and troubleshooting regardless of our clients' geographical locations. This remote support capability ensures that production continues smoothly and downtime is minimized, representing our commitment as reliable Two-wave Guardrail Roll Forming Machine Manufacturers to our clients' long-term success.

The guardrails produced using our equipment demonstrate exceptional consistency in mechanical properties and dimensional accuracy, complying with AASHTO M180 and EN 1317 standards. This reliability is crucial for ensuring predictable performance during vehicle impacts, ultimately contributing to enhanced road safety. Our position as trusted Two-wave Guardrail Roll Forming Machine Manufacturers is built on this commitment to quality and safety.

Choosing us as your Two-wave Guardrail Roll Forming Machine Manufacturers means investing in more than just equipment—it means partnering with experts dedicated to advancing highway safety through innovative manufacturing solutions. Our technical expertise, combined with our responsive support system, makes us the preferred choice for government agencies, construction firms, and guardrail specialists worldwide seeking reliable production solutions for their infrastructure projects.

Application Scenario

Our Certificate

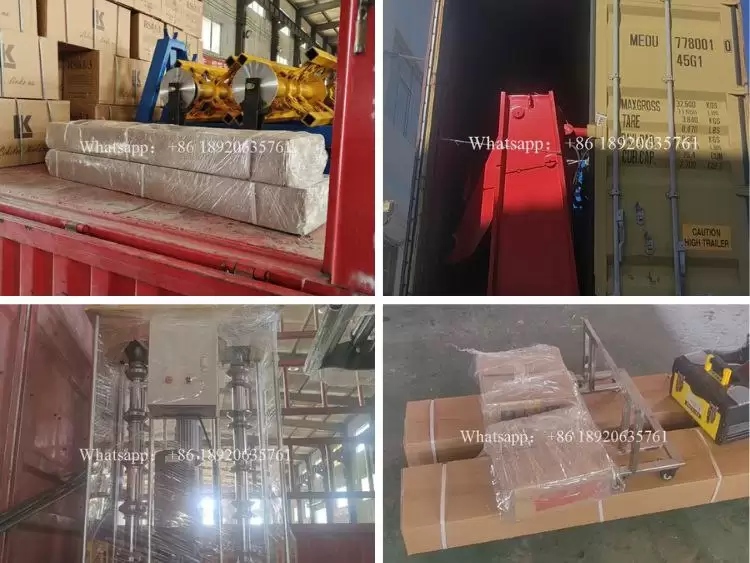

Our Transportation-and-delivery