Producto

Storage Rack Roll Forming Making Machinery for Storage Rack Bracing

Precision-Engineered with Our Storage Rack Roll Forming Making Machinery for Storage Rack Bracing

In the critical architecture of industrial storage systems, the bracing component is not merely an accessory; it is the essential diagonal backbone that ensures structural integrity, prevents sway, and guarantees safe load-bearing capacity under dynamic stresses. Manufacturing this vital part demands a production solution that prioritizes absolute precision, relentless consistency, and robust efficiency. Our dedicated Storage Rack Roll Forming Making Machinery for Storage Rack Bracing meets this demand head-on. This fully integrated, automated production line is expertly engineered to transform raw steel coil into high-strength, accurately punched rack braces, providing manufacturers with a complete, reliable, and high-output solution for this crucial component. Investing in our specialized Storage Rack Roll Forming Making Machinery for Storage Rack Bracing is an investment in the foundational safety and performance of your final storage rack product.

| Processing range of edge dimensions |

C40x29、C60x30、C80x40、C100x50

|

| Feeding thickness | 0.8-2.0 mm |

| Product Tolerances | Length: ±2 mm / for all processed lengths Width, Height: ±0.5 mm Other dimensions: Compliant with EN 10162 cold-rolled steel profiles standard |

| Forming speed | 0 - 40 meters/minute |

| Achieved Safety Standards (Design Safety Standards) | Designed according to CE standards; includes CO and CQ |

| Material waste during machine installation |

10-20 meters per adjustment |

| Total power |

30 kW

|

| Voltage | 380V, 50Hz, three-phase |

| Production line layout | (length x width) 14 x 2 (meters) |

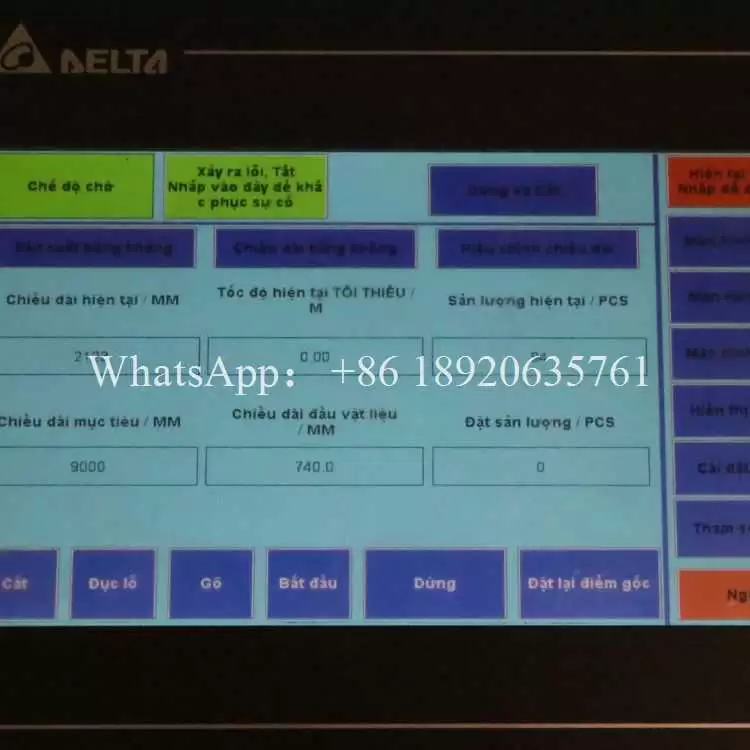

| Control system | PLC |

| Hydraulic System | Motor power: 5.5 kW * 2 Water tank capacity: 196 liters Working pressure: 12 MPa |

Workflow Diagram:Decoiler → Leveling → Roll forming → Punching → Servo cutting

The production excellence of our Storage Rack Roll Forming Making Machinery for Storage Rack Bracing is delivered through a seamless, automated sequence engineered for non-stop performance.

1.Decoiler & Leveling: The process is initiated by a precision decoiler that smoothly feeds steel coil into the system.

| Uncoiling method | Non-motorized decoiler |

| Coil outer diameter | 1800 mm |

| Coil inner diameter | 350-520 mm |

| Coil width | 50-300 mm |

| Coil load capacity | 3 tons |

| Expansion/contraction mechanism |

Manual

|

| Decoiler spindle shaft |

Material and hardness of the shaft raw material: Material: 45# steel, Hardness: 150-180 HB Diameter: 90 mm |

2. Roll forming: The material then progresses to the heart of the line: the advanced roll forming station. Here, through a meticulously designed and hardened set of roller dies, the flat metal strip is progressively cold-formed into the exact, often complex, profile required for optimal bracing strength and function.

| Roll forming motor power | 15 kW |

| Frame Material and Manufacturing Method | The frame is made of Q235 steel plate, welded and then precision-machined using a gantry milling machine |

| Height from the ground to the roll forming position | 800-850 (mm) |

| Transmission system | Gear drive |

| Number of roll forming pairs | 14 pairs of rollers |

| Roll forming shaft | Material, Hardness: 40Cr; Hardness: 250-280 HB Diameter: 65 mm |

| Rollers | Material, Hardness: Cr12; Hardness: 55-60 (HRC); Chrome plating thickness: 0.01-0.015 (mm) Diameter: 130 mm |

| Coil thickness | 35 mm |

3. Puching: Following this precise forming stage, state-of-the-art servo technology takes command. A high-precision servo punching unit performs clean, consistent, and burr-free hole perforations at exact intervals on the moving profile—a critical feature for secure bolted assembly.

| Punching speed | 30-35 (strokes per minute) |

| Punching force | T8-10 tons |

| Punching die | Material: Cr12MoV Die hardness: 56-58 (HRC) |

4. Servo cutting: The line culminates with a synchronized servo shear that delivers perfectly square, length-accurate cuts at high speeds.

| Cutting speed | 3-4 (per second) |

| Cutting blade angle | 45° |

| Cutting force | 8-10 tons |

| Cutting blade | Material: Cr12MoV Hardness: 58-62 (HRC) |

| Cutting capability | Servo cutting |

Understanding that diverse projects require tailored solutions, our Storage Rack Roll Forming Making Machinery for Storage Rack Bracing is designed with profound flexibility at its core. It is fully customizable to align with your specific product specifications and factory environment. Key operational parameters, including punching patterns and hole sizes, material entry width, roll forming thickness, and operating voltage, can all be precisely configured to your requirements. This ensures seamless integration into your production ecosystem and local power standards. Furthermore, our commitment extends far beyond the sale. To guarantee your operational success and minimize downtime, we provide unparalleled expert support through real-time video engineering guidance. Our specialists can offer immediate troubleshooting, maintenance advice, and operational optimization directly to your factory floor, ensuring your Storage Rack Roll Forming Making Machinery for Storage Rack Bracing maintains peak productivity and a rapid return on investment.

Application Scenario

Our photos with our customers

About us

HOPEX (Wuxi) Intelligent Technology Co., Ltd.: Pioneering Roll Forming Innovation Since 1996

Founded in 1996 with a dedicated R&D team for roll forming technology, HOPEX has evolved into a global force in intelligent manufacturing. Established in Wuxi in 2003, we launched our core product lines—semi-automatic purlin machines, cable tray machines, and guardrail machines—laying the foundation for our commitment to 100% customized solutions.In 2016, we doubled our team and expanded our offerings to include solar strut machines and heavy-duty leveling/slitting lines, while strengthening R&D for our flagship products. By 2022, HOPEX achieved 100% sales growth and revolutionized production through full automation, upgrading all equipment to smart manufacturing standards and growing our R&D team to 10+ experts.Today, we export cutting-edge machinery worldwide—serving Russia, Australia, India, the Middle East, Southeast Asia, and beyond—as we fully enter the global market in 2025. Our vision is clear: to be the global leader in roll forming technology, making precision engineering easier and hassle-free for industries everywhere.

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a premium Storage Rack Roll Forming Making Machinery for Storage Rack Bracing. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Storage Rack Roll Forming Making Machinery for Storage Rack Bracing be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.