Producto

Racking Beam Roll Form Machine Production Line For Storage System

Racking Beam Roll Form Machine Production Line for Storage System: Efficient and Customizable Solution for Metal Racking Beams

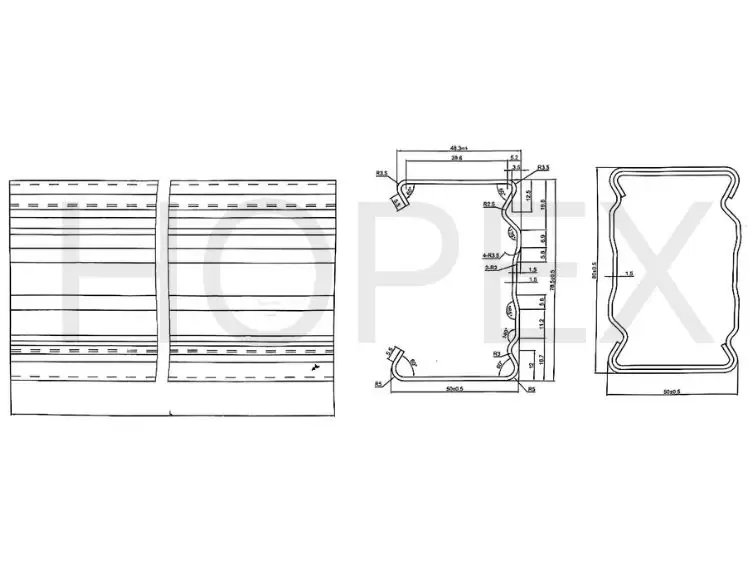

The Racking Beam Roll Form Machine Production Line for Storage System is an advanced, high-efficiency solution designed specifically for the production of metal racking beams used in storage systems. This fully automated production line ensures the seamless formation of metal beams that serve as critical components in shelving and racking structures. The machine line is capable of manufacturing beams where two interlocking products come together to form a complete racking beam, providing stability and support for heavy-duty storage systems in warehouses, retail spaces, and industrial settings.

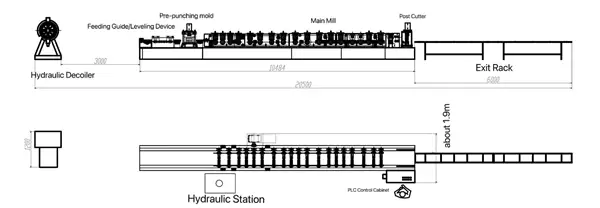

Workflow Diagram

The Racking Beam Roll Form Machine Production Line for Storage System consists of several integrated stages, each optimized to deliver high-quality, consistent results. The process is automated to reduce labor costs, improve production efficiency, and ensure precise manufacturing of racking beams.

Uncoiling (Decoiler):

The process begins with the decoiler, which unwinds the steel coil. The decoiler ensures that the coil is properly positioned for further processing, preventing any tangling or material damage. This stage is crucial for setting the material on the correct path to maintain a smooth and uninterrupted production process.

Roll Forming:

After uncoiling, the material moves to the roll forming station. This step is the heart of the Racking Beam Roll Form Machine Production Line for Storage System. Using precision rollers, the metal sheet is shaped into the desired profile. The roll forming process is highly customizable, allowing manufacturers to adjust parameters such as feed width, forming thickness, and the design of the beam to meet specific product requirements.

Hydraulic Cutting:

Once the metal has been shaped into the correct profile, it moves to the hydraulic shearing section. This cutting process is critical for ensuring that the racking beams are cut to the exact length required. The hydraulic system provides powerful cutting capabilities, allowing for precise cuts even with thick or high-strength materials. This step ensures uniformity and accuracy across all products.

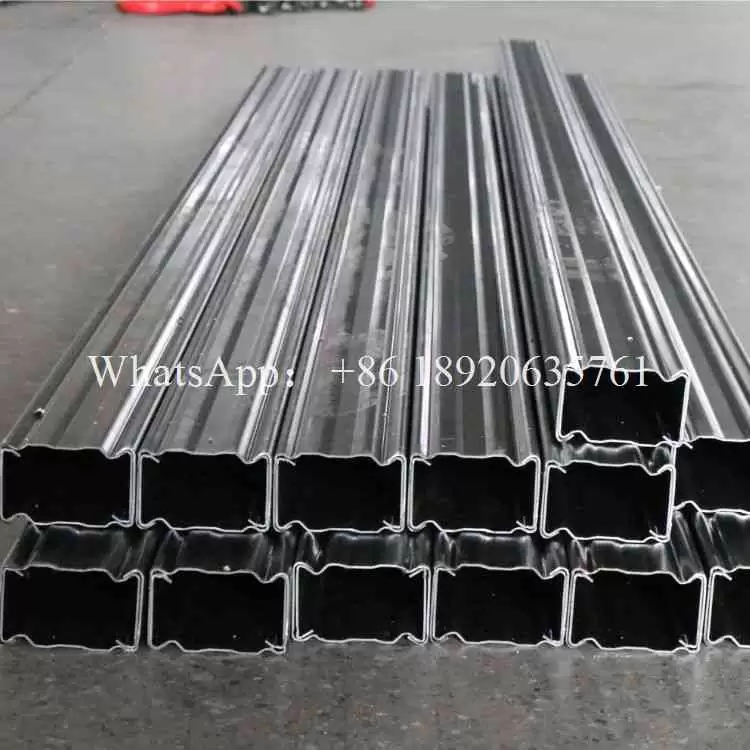

Snap-lock connection roll forming machine

The two interlocking products that make up the complete racking beam are formed here, providing the necessary structure and strength for storage systems.

Finished Product Receiving Rack:

After snap locking, the finished racking beams are transferred to the finished product receiving rack, where they are neatly stacked and prepared for packaging. This helps streamline the entire production process, improving overall productivity.

More parameters

| Product Name | Racking Beam Roll Form Machine Production Line |

| Main motor power | 15 kw(Siemens) |

| Hydraulic station | Vane pump, 7.5 kw |

| Produce speed | 20 m/min |

| Shaft material | 45# Steel |

| Brand of electrical control cabinet |

Phase sequence protector Independent cabinet |

| Touch screen | Siemens or customized according to customer requirements |

| Rolling materials | CCr12, hardness 55-60 (HRC), chrome plating thickness 0.01-0.015 (mm) |

| Roller diameter | 60 mm |

| Cutting blade material | Cr12MoV, hardness 58 - 62 (HRC) |

| Roller diameter | Φ75 mm |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 1.5 mm |

| Rows | 18-24(be customized) |

| Feeding width |

192±2 mm

|

| Product tolerance |

Length: +2 mm / all processed dimensions

Width, Height: ± 0.5 mm Other aspects: Tolerances for other dimensions (length, angles, etc.) shall conform to EN10162 cold-rolled steel profiles standard. |

| Dimensions (length × width × height) |

21 x 2 x 1.8 (meters)

|

| Weight | About 9 tons |

| Control system | PLC |

| Total power | 42 kw |

| Output material handling rack-Table length | 3m ×2 |

One of the key advantages of the Racking Beam Roll Form Machine Production Line for Storage System is its high level of customization. The machine allows for adjustments to key parameters such as feed width, forming thickness, and voltage to meet specific production needs. Whether you are producing beams for standard storage systems or need to meet specialized requirements, this flexibility allows manufacturers to cater to a wide range of customer demands.

The Racking Beam Roll Form Machine Production Line for Storage System is fully automated, ensuring that the entire process from uncoiling to stacking is seamless and efficient. Automation reduces the need for manual intervention, decreasing labor costs and increasing production speeds. Additionally, automated processes ensure high-quality, consistent results in every production cycle, which is crucial for industries where precision and reliability are paramount.

In the event of any technical issues, the Racking Beam Roll Form Machine Production Line for Storage System offers remote video guidance. Engineers can provide real-time troubleshooting and technical support through video consultations, ensuring minimal downtime and allowing the production process to continue without disruption. This remote support option is particularly valuable for manufacturers looking to maintain smooth operations without the need for extensive on-site visits.

Application Scenario

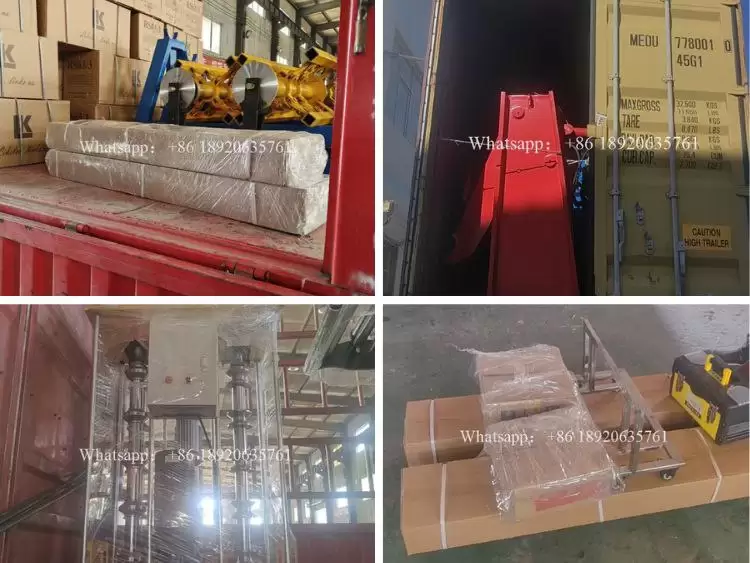

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for a Racking Beam Roll Form Machine Production Line for Storage System. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Racking Beam Roll Form Machine Production Line for Storage System be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.