Producto

Light Villa Gauge Steel Roll Forming Machine

Innovate Your Building Solutions with Our Advanced Light Gauge Steel Roll Forming Machine

The construction industry is rapidly evolving, with an increasing demand for building methods that are not only faster and more efficient but also environmentally sustainable. Light gauge steel framing has emerged as a premier solution, offering exceptional strength, durability, and design flexibility for modern structures. As a specialized manufacturer in cold roll forming technology, we are proud to introduce our high-precision light gauge steel roll forming machine. This complete production line is engineered to fabricate the essential components for resilient buildings, empowering manufacturers to lead in the dynamic market of prefabricated construction.

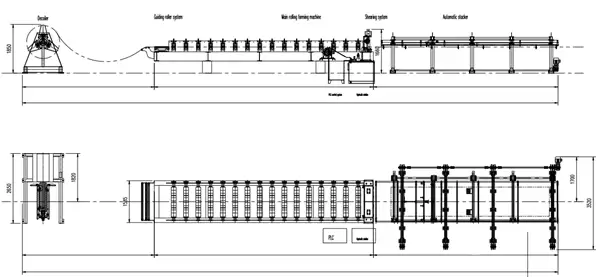

Roll Forming Process Workflow Diagram

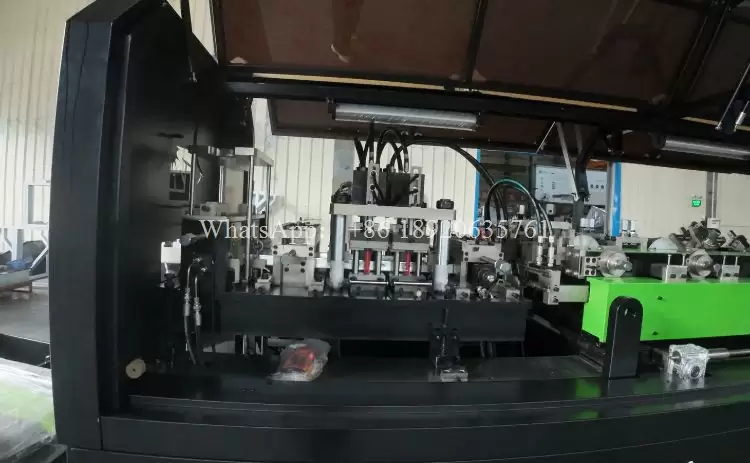

Our light gauge steel roll forming machine represents the pinnacle of automation and precision in profile manufacturing. Designed for continuous operation, this robust system efficiently produces a wide array of critical components, including studs, tracks, joists, and channels. These elements form the skeleton of various structures, from residential villas and apartment complexes to commercial buildings and industrial facilities. The exceptional accuracy of our light gauge steel roll forming machine guarantees that every profile meets exact dimensional tolerances, ensuring seamless and swift on-site assembly. This results in significant reductions in construction time, material waste, and overall project costs.

More parameters

| Product Name |

Light Villa Gauge Steel Roll Forming Machine |

| Main motor power | 7.5 kw*2 |

| Opening and closing servo motor power | 4 kw |

| Produce speed |

20 m/min

|

| Shaft material | 45# Steel |

| Touch screen | Delta or customized according to customer requirements |

| Rolling materials | Cr12mov |

| Cutting blade material | Cr12 |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 0.4-1.2mm |

| Rows | 18 |

Versatility is a cornerstone of this system. Our light gauge steel roll forming machine can be precisely calibrated to produce diverse profiles, thicknesses, and lengths, catering to unique architectural designs and specific engineering requirements. To facilitate a rapid project commencement, we commit to a swift 3-day drawing approval process. Our expert engineering team provides comprehensive technical drawings for your review, ensuring the machine configuration perfectly aligns with your production goals before manufacturing begins.

We understand that reliable technical support is crucial for your operational success. To this end, we offer extensive remote assistance through real-time video conferencing. Our experienced engineers provide remote commissioning, operational training, and prompt troubleshooting, ensuring your light gauge steel roll forming machine maintains optimal performance with minimal downtime. This dedicated remote warranty service provides you with peace of mind and expert guidance whenever needed.

Investing in our light gauge steel roll forming machine is an investment in the future of construction. It enhances your production capability, ensures consistent product quality, and provides a significant competitive advantage. This machine is the ideal solution for forward-thinking manufacturers dedicated to excellence in the modern building industry.

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the Light Villa Gauge Steel Roll Forming Machine. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Light Villa Gauge Steel Roll Forming Machine be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.