Product

Automated villa house steel frame machine line

Villa House Steel Frame Machine Line: Revolutionizing Custom Villa Construction with Automated Precision

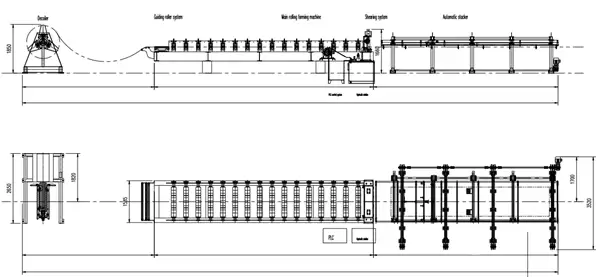

The villa house steel frame machine line represents the pinnacle of modern construction technology, transforming raw steel coils into precision structural components for high-end villas in a single automated process. This integrated system combines five critical stages - decoiling, leveling, roll forming, cutting, and stacking - to deliver unparalleled efficiency in custom steel frame manufacturing.

Roll Forming Process Workflow Diagram

More parameters

| Product Name | |

| Main motor power | 7.5 kw*2 |

| Opening and closing servo motor power | 4 kw |

| Produce speed |

20 m/min

|

| Shaft material | 45# Steel |

| Touch screen | Delta or customized according to customer requirements |

| Rolling materials | Cr12mov |

| Cutting blade material | Cr12 |

| Voltage | 380v 50hz 3p be customized |

| Feeding thickness | 0.4-1.2mm |

| Rows | 18 |

Core Workflow Breakdown

Intelligent Decoiling: The process begins with servo-controlled decoilers feeding high-strength steel coils into the system. Our villa house steel frame machine line features dual coil cars enabling continuous production, reducing downtime compared to manual handling.

Precision Leveling: Multi-roller leveling stations eliminate material stresses and ensure flatness tolerances within ±0.3mm/m. This critical step in the villa house steel frame machine line guarantees dimensional accuracy for complex architectural designs.

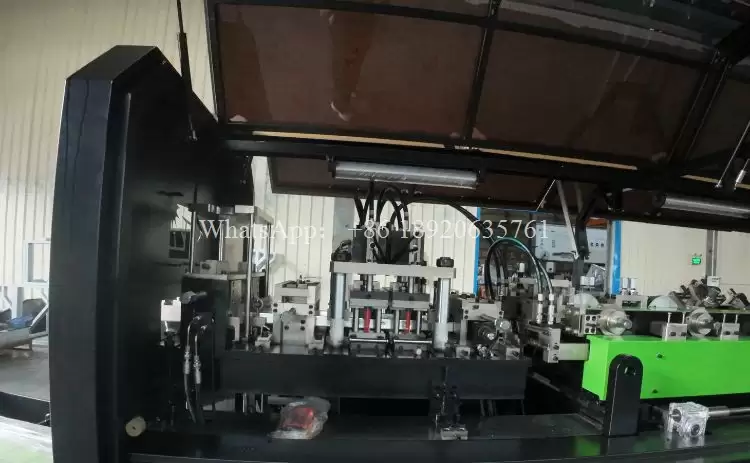

Adaptive Roll Forming: At the heart of the villa house steel frame machine line, 18 stations of CNC-adjusted forming rolls progressively shape steel into customized C/U channels and tracks. The patent-pending quick-change system allows profile switching in under 15 minutes, accommodating everything from standard 50mm to bespoke 200mm sections.

Programmable Cutting: High-frequency servo flying shears achieve ±1.0 mm cutting accuracy at speeds up to 20 m/min. The villa house steel frame machine line integrates laser measurement for automatic length compensation, ensuring a perfect fit for prefabricated villa modules.

Robotic Stacking: Industrial robots with vacuum lifters organize finished frames into palletized bundles. This final phase of the villa house steel frame machine line incorporates AI-powered pattern recognition to optimize loading density, reducing shipping costs.

Our photos with our customers

FAQ

Q: Are you a trading company or a factory?

A: We are a factory with a professional production team and service consciousness, just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style of panel profile?

A: Not complete. Suitable for the Automated villa house steel frame machine line. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the Automated villa house steel frame machine line be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing, and packaging on the roll surface and shaft.

Q: What can you do if the machine breaks?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation, and we provide technical support for the entire life cycle of the device.