What are the uses of cable trays?

The solar channel roll forming machine represents a cornerstone technology in the rapidly expanding renewable energy sector, specifically designed to manufacture precision components for photovoltaic mounting systems. As a specialized roll forming machine for solar structure production, this equipment transforms raw metal coils into high-strength structural elements that form the backbone of solar panel installations worldwide. The solar bracket roll forming machine category encompasses sophisticated manufacturing systems that combine precision engineering with robust construction to meet the demanding requirements of solar infrastructure projects.

These advanced manufacturing systems have evolved significantly to address the specific needs of solar farm developers and mounting system manufacturers. The photovoltaic bracket roll forming machine delivers exceptional dimensional accuracy and consistent quality across high-volume production runs, ensuring that every component meets stringent structural requirements for solar installations. From rooftop arrays to utility-scale solar farms, the channels produced by these machines provide reliable support for photovoltaic panels across diverse environments and applications.

In-Depth Manufacturing Process Analysis

Uncoiling and Precision Leveling Systems

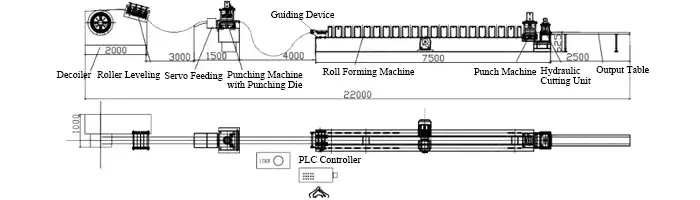

The production process begins with sophisticated uncoiling mechanisms that handle large metal coils with precision and consistency. These systems incorporate automatic tension control and alignment features to ensure smooth material feeding into the solar panel mounting structure roll forming machine. Following uncoiling, the material passes through a multi-roller leveling unit that eliminates any irregularities, curvature, or internal stresses from the metal strip. This critical preparatory stage ensures perfect flatness before the forming process, directly impacting the final product's quality and dimensional stability.

Precision Punching Operations

Modern solar strut roll forming machines integrate high-precision punching stations that create accurately positioned holes, slots, and notches according to specific design requirements. These punching units feature programmable servo-driven mechanisms that enable quick changeovers between different hole patterns and spacing configurations. The flexibility of these systems allows manufacturers to produce customized solar strut channel roll forming machine outputs with varying hole arrangements for different mounting applications, including specialized patterns for specific racking system designs and compatibility with various clamping mechanisms.

Advanced Roll Forming Technology

The heart of the solar channel roll forming machine is its precision forming section, where a series of meticulously engineered roll stations progressively shape the flat metal strip into the final channel profile. Each station contributes incrementally to the forming process, ensuring material integrity while achieving the exact geometrical specifications required for solar mounting applications. The solar panel mounting bracket roll forming machine typically incorporates between 12 to 18 forming stations, depending on the complexity of the profile and material thickness capabilities.

Hydraulic Cutting and Finishing

The final stage in the production process involves precision cutting using advanced hydraulic systems that synchronize perfectly with the forming section. These cutting units deliver clean, burr-free edges with exceptional accuracy, maintaining tight tolerances across continuous production runs. The integration of programmable logic controllers (PLC) throughout the solar bracket roll forming machine ensures seamless coordination between all stations, optimizing production efficiency while minimizing material waste.

Solar Channel Profiles and Classification

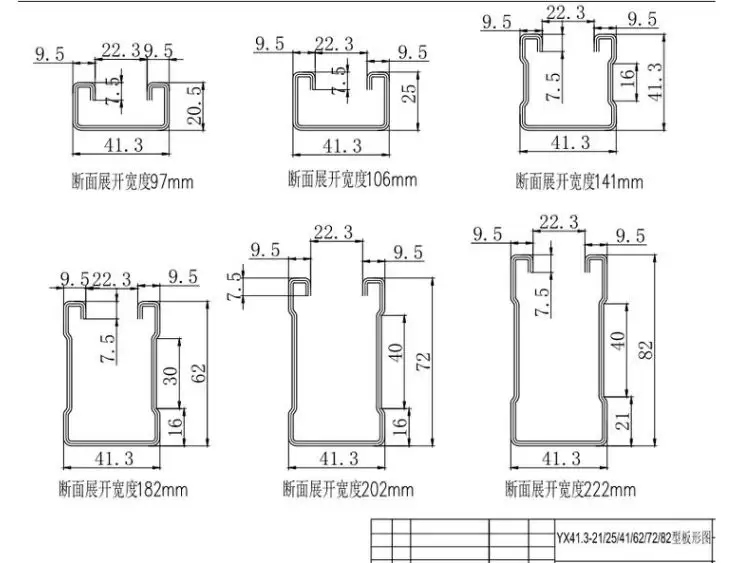

C-Type Solar Channels

C-shaped channels represent one of the most common profiles produced by solar strut channel roll forming machines, characterized by their distinctive open-channel design with inward-curving lips at the top edges. These channels offer excellent load-bearing capacity while providing convenient access for bolt placement and adjustment. The C-profile configuration makes them ideal for a wide range of mounting applications, particularly where accessibility and adjustability are prioritized. Manufacturers can produce various C-channel dimensions using the same solar panel mounting bracket roll forming machine through quick tooling adjustments and parameter modifications.

U-Type Solar Channels

U-shaped channels feature a simpler rectangular design with straight vertical sides, providing maximum material strength and straightforward installation characteristics. The solar channel roll forming machine configured for U-profiles produces components with consistent dimensional accuracy, ensuring perfect fitment during assembly operations. These channels typically offer higher torsional resistance compared to C-profiles and are commonly used in applications where structural integrity takes precedence over adjustability requirements.

Custom and Hybrid Profiles

Beyond standard C and U profiles, modern photovoltaic bracket roll forming machines can be configured to produce various custom and hybrid channel designs tailored to specific mounting system requirements. These may include specialized profiles with reinforced edges, integrated wiring channels, or unique geometries that address particular installation challenges. The flexibility of contemporary solar panel mounting structure roll forming machine systems enables manufacturers to respond quickly to evolving market demands and custom project specifications. View more...→

Applications and Implementation Scenarios

Commercial and Industrial Rooftop Installations

The channels produced by solar strut roll forming machines form the primary structural framework for countless commercial and industrial rooftop solar installations. These applications demand precision components that can withstand environmental exposure while supporting significant static and dynamic loads. The consistency and quality assurance provided by modern solar bracket roll forming machine systems ensure that every channel meets the engineering specifications required for safe, long-lasting rooftop installations.

Utility-Scale Ground Mount Systems

For large-scale solar farms, the solar channel roll forming machine produces the essential components that form extensive mounting structures supporting thousands of photovoltaic panels. These applications require exceptional dimensional consistency across high-volume production runs to ensure seamless assembly and structural integrity across vast installation areas. The efficiency of contemporary solar panel mounting bracket roll forming machine systems enables manufacturers to meet the demanding production schedules associated with utility-scale solar projects.

Specialized Solar Applications

Beyond conventional installations, channels manufactured using solar strut channel roll forming machines serve numerous specialized applications, including solar carports, building-integrated photovoltaics (BIPV), floating solar arrays, and tracking systems. Each application presents unique requirements that the photovoltaic bracket roll forming machine must accommodate through precise profile geometry and consistent mechanical properties across production batches.

Technical Advantages and Performance Benefits

Production Efficiency and Throughput

Modern solar channel roll forming machines deliver exceptional production efficiency, with typical operating speeds ranging from 15 to 35 meters per minute depending on material thickness and profile complexity. This high-throughput capability enables manufacturers to meet demanding project timelines while maintaining consistent quality across production runs. The automated nature of these systems reduces labor requirements while maximizing output, providing significant economic advantages for mounting system manufacturers.

Material Utilization and Sustainability

The solar bracket roll forming machine process offers excellent material utilization efficiency, minimizing waste through precision forming and cutting operations. This efficiency translates directly to cost savings and reduced environmental impact, aligning with the sustainability principles inherent to the solar industry. Additionally, the compatibility of these systems with various recyclable materials further enhances their environmental credentials.

Quality Consistency and Dimensional Accuracy

The precision engineering incorporated into contemporary solar panel mounting structure roll forming machine systems ensures exceptional dimensional consistency across production runs, with typical tolerances maintained within ±0.5mm for critical dimensions. This consistency directly translates to easier installation, reduced assembly time, and improved structural performance in the field. The reliability of components produced by solar strut channel roll forming machines contributes significantly to the long-term performance and durability of solar installations.

The continued advancement of solar channel roll forming machine technology plays a vital role in supporting the global transition to renewable energy by enabling efficient, cost-effective production of high-quality mounting system components. As solar installation volumes continue to grow worldwide, these sophisticated manufacturing systems will remain essential to meeting the infrastructure demands of the expanding photovoltaic industry.