Cable tray roll forming machines represent a cornerstone technology in modern industrial infrastructure, enabling efficient production of cable management systems that organize and protect vital electrical and data cables across countless applications. As a cable tray machine manufacturer, understanding the sophisticated engineering behind these production lines is essential for delivering quality systems that meet diverse industrial requirements.

The Advanced Production Process of Cable Tray Manufacturing Machines

A complete cable tray production line integrates multiple specialized stations that transform raw materials into finished cable trays with minimal operator intervention. This sophisticated arrangement represents the pinnacle of modern industrial automation for cable tray manufacturing.

Uncoiling and Leveling: The process begins with an automatic uncoiler that feeds coiled metal into the system. This material then passes through a leveling unit that removes any irregularities or stresses, ensuring perfect flatness before forming. This critical first step guarantees the dimensional accuracy of the final product.

Precision Punching: The material next advances to the punching station, where a specialized cable tray punching machine creates precisely positioned holes for mounting, ventilation, or cable access. Modern systems feature programmable punching patterns that can be adjusted instantly for different tray designs, including specialized trench cable tray configurations.

Hydraulic Cutting: Following punching, a hydraulic cutting unit shears the continuous metal strip into predetermined lengths. This cable tray cutting machine component operates with exceptional accuracy, ensuring clean, burr-free edges on every piece. The cutting mechanism synchronizes perfectly with the forming section to maintain consistent production flow.

Roll Forming: The heart of the system is the cable tray forming machine section, where a series of precision-engineered rollers gradually shape the flat metal into the final tray profile. Each station contributes to the progressive formation, with the cable tray bending machine aspects carefully calibrated to achieve the exact geometry without compromising material integrity.

The entire process exemplifies efficiency in cable tray manufacturing, with typical production speeds reaching 4-6 meters per minute for standard systems, while advanced configurations can achieve up to 10-15 meters per minute.

Cable Tray Classification and Product Advantages

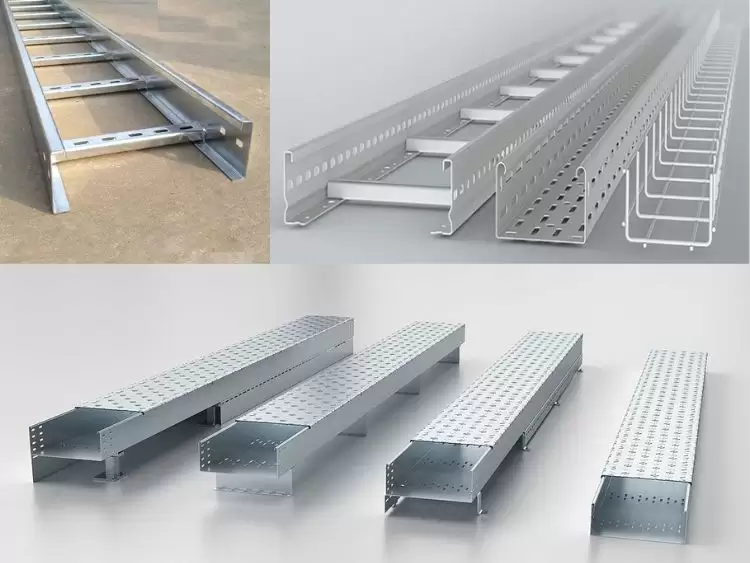

The versatility of cable tray roll forming machines enables manufacturers to produce various tray types, each designed for specific applications and performance characteristics:

Ladder-Type Cable Trays: Characterized by their distinctive rung construction, these trays offer superior ventilation and are ideal for supporting large-diameter power cables. Their open design facilitates heat dissipation and allows easy visual inspection of cables .

Trough/Trench Cable Trays: These feature a solid bottom with partial side walls, providing enhanced protection against dust, moisture, and physical contact while still allowing some ventilation. Trench cable tray systems are particularly valuable in environments where some cable protection is needed but complete enclosure isn't required.

Solid Bottom Trays: With fully enclosed bases, these trays offer maximum protection against dust, moisture, and physical damage. They're essential for applications requiring superior cable shielding or where regulations mandate complete containment .

The manufacturing flexibility of cable tray making machine systems allows producers to easily switch between these configurations, responding quickly to market demands. This adaptability extends to material choices as well, with most machines processing galvanized steel, stainless steel, or aluminum with equal proficiency .

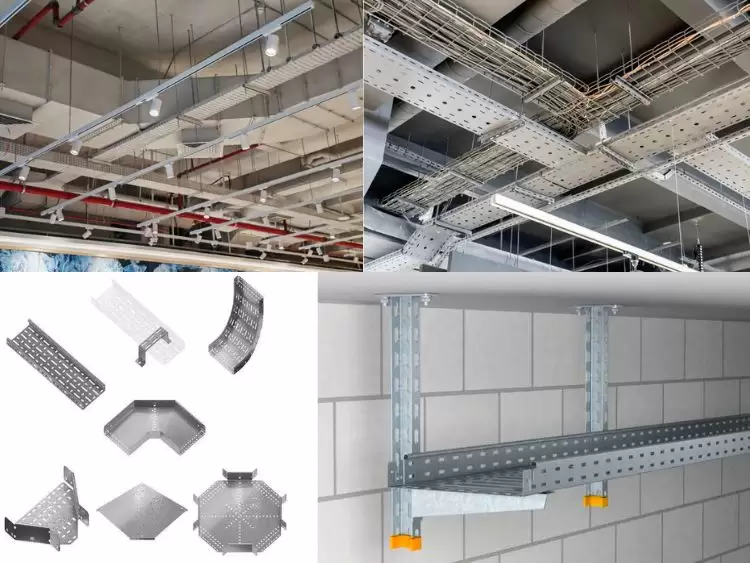

Application Environments for Cable Trays

Cable trays produced by cable tray roll forming machines serve critical functions across diverse sectors:

Industrial Facilities: In manufacturing plants, refineries, and processing facilities, cable trays organize and protect power distribution and control system wiring. Their robust construction withstands harsh environments while maintaining accessibility for maintenance and modifications .

Commercial and Institutional Buildings: Modern office complexes, hospitals, and educational institutions rely on cable trays to manage the extensive electrical and data infrastructure that supports daily operations. The aesthetic flexibility of cable trays allows for both exposed and concealed installations.

Data Centers and Telecommunications: These mission-critical facilities require precise cable management to ensure optimal system performance and cooling efficiency. Cable trays provide the necessary organization and support for thousands of cables in limited spaces .

Public Infrastructure and Transportation: Airports, train stations, and utility networks employ cable trays to protect essential power and communication lines that serve public needs. The corrosion-resistant finishes available on trays produced by modern cable tray manufacturing machine systems ensure longevity even in demanding environments .

Our Advantages

Technical Specifications: We provide comprehensive technical documentation, including production speeds (typically 4-15 m/min), material thickness capabilities (usually 0.8-2.0mm), power requirements (approximately 40KW for complete lines), and dimensional ranges for width (100-600mm) and height (50-200mm) .

Control Systems and Automation: Modern cable tray production line equipment incorporates PLC-based controls, often featuring brands like Mitsubishi for reliability. These systems allow for precise adjustment of all production parameters and quick changeovers between different tray profiles .

Build Quality and Durability: The construction of the cable tray roll forming machine directly impacts its longevity and maintenance requirements. Critical components like shafts made from Cr12Mov steel and precision-machined rollers ensure consistent performance under continuous operation .

Support Services and Warranty: Leading cable tray roll forming machine manufacturers stand behind their equipment with comprehensive warranties (typically one year) and after-sales support, including the availability of engineers for overseas service when needed .View more...→

Conclusion

Cable tray roll forming machines represent sophisticated manufacturing platforms that efficiently produce essential components for modern cable management. From the individual cable tray punching machine and cable tray cutting machine stations to the complete integrated cable tray production line, these systems enable manufacturers to respond to diverse market needs with precision and efficiency. As infrastructure development continues globally, the demand for high-quality cable trays produced by advanced cable tray forming machine technology will only grow, creating ongoing opportunities for knowledgeable manufacturers in this specialized field.