The Engine of Solar Expansion: Roll Forming Machine For Solar Structure

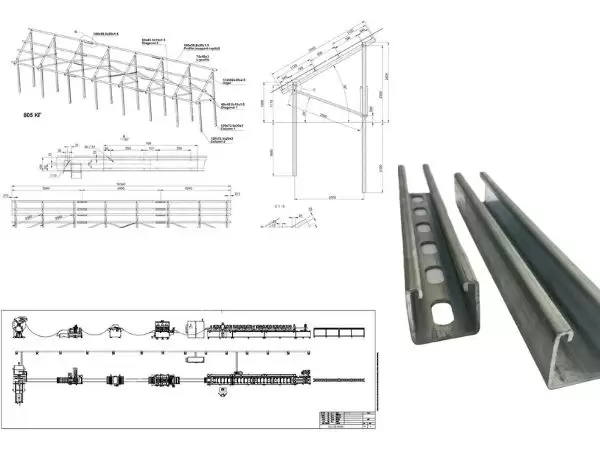

The global surge in solar energy deployment is fundamentally reshaping power generation. At the heart of every efficient, reliable, and long-lasting solar installation – from vast utility-scale farms to commercial rooftops – lies the critical solar mounting structure. These structural frameworks provide the essential foundation, support, and precise positioning for photovoltaic (PV) panels. Manufacturing these structures efficiently, consistently, and cost-effectively requires specialized technology: the roll forming machine for solar structure. This sophisticated machinery is the cornerstone of producing the high-quality rails, beams, purlins, and clamps that form the backbone of the solar industry.

The Vital Role of Solar Mounting Structures (PV Racking)

Solar mounting structures are far more than simple metal frames. They are engineered systems designed for decades of performance under demanding environmental conditions, serving crucial functions:

Optimal Panel Positioning: Precisely tilt and orient panels to maximize exposure to sunlight throughout the day and year, directly impacting energy yield.

Secure Anchoring: Provide robust mechanical attachment for PV panels, ensuring they withstand high winds, snow loads, seismic activity, and other environmental stresses over a 25+ year lifespan.

System Integrity & Safety: Create a stable, unified structure that prevents panel movement, micro-cracks, and potential failure points, safeguarding both the investment and personnel.

Ground Clearance & Ventilation: Elevate panels above roofs or ground surfaces, allowing for cooling airflow (improving efficiency) and preventing debris/water accumulation or vegetation interference.

Simplified Installation & Maintenance: Engineered components designed for rapid, standardized assembly in the field, reducing labor costs and complexity. Facilitates access for inspection and cleaning.

Site Adaptation: Designed for diverse applications: flat roofs, sloped roofs, ground mounts, carports, trackers, and even floating systems.

Where Solar Structures Are Deployed: Key Applications

Utility-Scale Solar Farms (Ground Mounts): The largest application. Miles of robust structures, often pile-driven or ground-screw mounted, support vast arrays of panels. Demands high-volume production of standardized, durable components.

Commercial & Industrial (C&I) Rooftops: Structures must be lightweight yet strong, adaptable to various roof types (ballasted, penetrated, or hybrid), and minimize roof loading and penetration risks. Low-profile designs are common.

Residential Rooftops: Smaller scale, but requires precision, aesthetics, and compatibility with diverse roof materials and slopes. Often uses simplified rail-based systems.

Solar Carports & Canopies: Dual-purpose structures providing shade/cover while generating power. Requires significant structural strength for span and load-bearing, plus integrated cable management.

Agricultural Solar (Agrivoltaics): Structures are elevated to allow farming activities beneath panels, requiring specific height clearances and durability in agricultural environments.

Floating Solar: Specialized structures designed to mount panels on pontoons in reservoirs or ponds, demanding corrosion resistance and unique anchoring.

Why Roll Forming is Ideal for Solar Structures:

High Speed & Volume: Continuous operation enables production of very long lengths (hundreds of meters) at high linear speeds, unmatched by press braking or extrusion for these profiles. Essential for meeting global solar demand.

Exceptional Consistency & Precision: Every meter of profile produced is identical. This ensures perfect fit, compatibility, and ease of assembly in the field – critical for structural integrity and the secure mounting of panels and clamps. Tight tolerances are maintained consistently.

Material Efficiency & Low Waste: Starting from coiled metal minimizes scrap compared to cutting parts from sheets. Progressive bending also induces less stress than heavy single-stamp press braking.

Design Flexibility & Customization: Modern roll forming machines for solar structure are highly adaptable. By changing the roller die sets, a single machine can produce a vast array of complex rail profiles (e.g., C-section, U-section, custom geometries), purlins, clamps, and even integrated cable management channels to meet diverse project specifications and evolving international standards.

Cost-Effectiveness: The combination of high throughput, material efficiency, reduced labor (due to simplified assembly of consistent parts), and minimized scrap translates into a significantly lower overall cost per meter of finished structure. This directly impacts the Levelized Cost of Energy (LCOE) for solar projects.

Strength & Durability: The cold-forming process can induce beneficial work-hardening in the metal. The resulting profiles are structurally efficient, offering excellent strength-to-weight ratios necessary to support heavy panels and withstand decades of wind, snow, and dynamic loads.

Surface Integrity: Roll forming minimizes surface marring compared to other forming processes, preserving the protective coatings (galvanization, ZAM, Magnelis, paint) crucial for long-term corrosion resistance.

Conclusion: Powering the Future from the Ground Up

As the world accelerates its transition to renewable energy, the demand for robust, reliable, and rapidly deployable solar infrastructure continues to surge. The roll forming machine for solar structure is not just a piece of factory equipment; it is a critical enabler of the solar revolution. By providing the means to manufacture the essential mounting structures with unparalleled speed, precision, flexibility, and cost-efficiency, this technology underpins the quality, scalability, and bankability of solar projects worldwide. Investing in advanced roll forming machine for solar structure technology is an investment in the future of solar energy. It ensures that the foundations upon which our PV panels are mounted are as strong, durable, and efficient as the sunlight they capture, ultimately contributing to a more sustainable and energy-secure world. The precision and productivity delivered by the roll forming machine for solar structure truly make it the engine driving the global expansion of solar power.