The Backbone of Modern Infrastructure: Cable Tray Roll Forming Machines

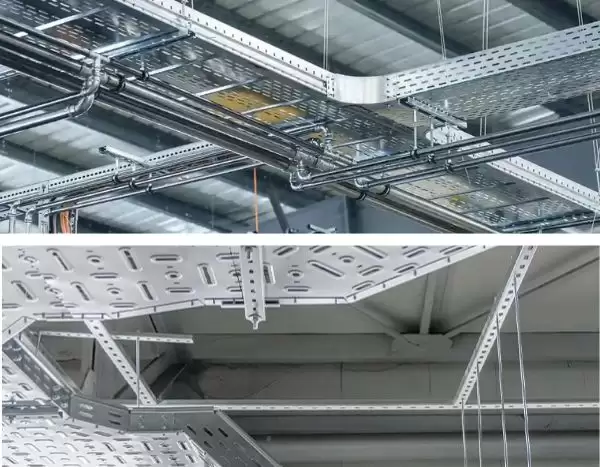

In the intricate network of modern construction and industrial facilities, safely and efficiently managing electrical wiring, data cables, and communication lines is paramount. This critical task falls upon cable tray systems, the unsung heroes supporting the vital nervous systems of buildings, factories, data centers, and infrastructure projects. At the heart of manufacturing these essential components lies the sophisticated technology of the cable tray roll forming machine.

Understanding Cable Trays: Purpose and Pervasiveness

Cable trays are essentially structured systems designed to securely support and route large volumes of cables overhead or underfloor. Unlike traditional conduit, which encases individual cables or small bundles, trays offer an open, accessible, and highly flexible solution. They are ubiquitous across numerous sectors:

Industrial Facilities: Manufacturing plants, refineries, chemical plants, and power generation stations rely heavily on robust cable trays to manage complex power distribution, control wiring, and instrumentation cabling in harsh environments. Their strength, accessibility for maintenance, and ability to handle large cable volumes are indispensable.

Commercial Buildings: Office towers, shopping malls, hospitals, and educational institutions use trays extensively for power distribution, lighting circuits, data networks (LAN/CATx/Fiber), fire alarm systems, and security wiring above ceilings and below floors.

Data Centers & Telecommunications: The massive concentration of server racks and networking equipment requires high-density, well-organized cable management. Perforated trays and wire mesh trays are vital for airflow management (critical for cooling) and easy access for frequent cable modifications.

Infrastructure Projects: Airports, train stations, stadiums, tunnels, and bridges utilize cable trays for lighting, power, control systems, communication networks, and security installations due to their durability and adaptability to large-scale designs.

Residential Complexes: Increasingly used in large apartment buildings and complexes for backbone power and communication distribution.

The Critical Role of the Cable Tray Roll Forming Machine

Manufacturing cable trays efficiently, consistently, and cost-effectively to meet diverse project specifications is a complex challenge. This is where the specialized cable tray roll forming machine becomes the cornerstone of production. This advanced manufacturing line transforms continuous coils of raw metal (typically pre-painted galvanized steel, stainless steel, or aluminum) into the precise profiles required for cable tray components – primarily side rails (strings) and rungs (cross members).

Why the Cable Tray Roll Forming Machine is Indispensable

The adoption of a dedicated cable tray roll forming machine offers transformative advantages over alternative manufacturing methods like press braking or manual fabrication:

Unmatched Efficiency & Speed: Continuous operation allows for the production of long lengths of profile at high linear speeds (often meters per minute), dramatically increasing output compared to discrete part methods.

Consistent Precision & Quality: The roll forming process ensures every inch of the produced profile has identical dimensions and tolerances. This consistency is crucial for the easy assembly of trays on-site and structural integrity.

Material Savings & Reduced Waste: Roll forming is a highly efficient process with minimal material waste compared to cutting and bending individual pieces. Precise control optimizes material usage.

Complex Profile Capability: These machines can create intricate cross-sections with multiple bends and flanges necessary for the strength and functionality of cable trays – profiles often impossible or prohibitively expensive to make otherwise.

Lower Labor Costs & Operator Skill Requirements: Once set up and programmed, the automated cable tray roll forming machine line requires minimal operator intervention compared to labor-intensive manual processes.

Flexibility & Quick Changeovers: Modern lines with advanced control systems allow for relatively fast switching between different cable tray profiles and sizes by changing roll sets and reprogramming parameters.

Strength & Structural Integrity: The cold-forming process work-hardens the metal, often resulting in a stronger final product compared to hot-rolled alternatives. The continuous nature also avoids weak points like weld seams along the length.

For manufacturers supplying the construction and industrial sectors, a state-of-the-art cable tray roll forming machine is not just a piece of equipment; it's a strategic investment. It enables the production of high-quality, cost-competitive cable tray systems that meet the demanding requirements of modern infrastructure projects. The efficiency, precision, and flexibility provided by these machines are fundamental to keeping pace with global demand for safe, reliable, and accessible cable management solutions.

As buildings become smarter and industries more automated, the need for robust cable management grows exponentially. The cable tray roll forming machine stands as the essential technology enabling the mass production of the very backbone that supports the wires and cables powering our world. Choosing the right cable tray roll forming machine line is critical for manufacturers aiming to lead in this vital market.